Introduction

All electronic components, from microprocessors to high end powerconverters, generate heat and rejection of this heat is necessary for theiroptimum and reliable operation. As electronic design allows higher throughputin smaller packages, dissipating the heat load becomes a critical design factor. Many of today’s electronic devices require cooling beyond the capability ofstandard metallic heat sinks. The heat pipe is meeting this need and is rapidlybecoming a main stream thermal management tool.

Heat pipes have been commercially available since the mid 1960’s. Only inthe past few years, however, has the electronics industry embraced heat pipes asreliable, cost-effective solutions for high end cooling applications. Thepurpose of this article is to explain basic heat pipe operation, review key heatpipe design issues, and to discuss current heat pipe electronic coolingapplications.

Heat Pipe Operation

A heat pipe is essentially a passive heat transfer device with an extremelyhigh effective thermal conductivity. The two-phase heat transfer mechanismresults in heat transfer capabilities from one hundred to several thousand timesthat of an equivalent piece of copper.

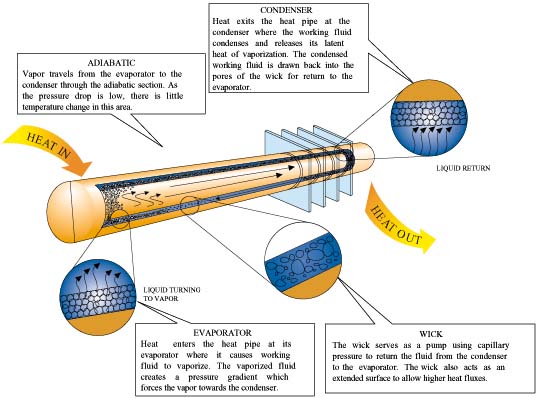

As shown in Figure 1, the heat pipe in its simplest configuration is aclosed, evacuated cylindrical vessel with the internal walls lined with acapillary structure or wick that is saturated with a working fluid. Since theheat pipe is evacuated and then charged with the working fluid prior to beingsealed, the internal pressure is set by the vapor pressure of the fluid.

As heat is input at the evaporator, fluid is vaporized, creating a pressuregradient in the pipe. This pressure gradient forces the vapor to flow along thepipe to a cooler section where it condenses giving up its latent heat ofvaporization. The working fluid is then returned to the evaporator by thecapillary forces developed in the wick structure.

Heat pipes can be designed to operate over a very broad range oftemperatures from cryogenic (< -243°C) applications utilizing titaniumalloy/nitrogen heat pipes, to high temperature applications (>2000°C)using tungsten/silver heat pipes. In electronic cooling applications where it isdesirable to maintain junction temperatures below 125-150°C, copper/waterheat pipes are typically used. Copper/methanol heat pipes are used if theapplication requires heat pipe operation below 0°C.

Heat Pipe Design

There are many factors to consider when designing a heat pipe: compatibilityof materials, operating temperature range, diameter, power limitations, thermalresistances, and operating orientation. However, the design issues are reducedto two major considerations by limiting the selection to copper/water heat pipesfor cooling electronics. These considerations are the amount of power the heatpipe is capable of carrying and its effective thermal resistance. These twomajor heat pipe design criteria are discussed below.

Limits To Heat Transport

The most important heat pipe design consideration is the amount of power theheat pipe is capable of transferring. Heat pipes can be designed to carry a fewwatts or several kilowatts, depending on the application. Heat pipes cantransfer much higher powers for a given temperature gradient than even the bestmetallic conductors. If driven beyond its capacity, however, the effectivethermal conductivity of the heat pipe will be significantly reduced. Therefore,it is important to assure that the heat pipe is designed to safely transportthe required heat load.

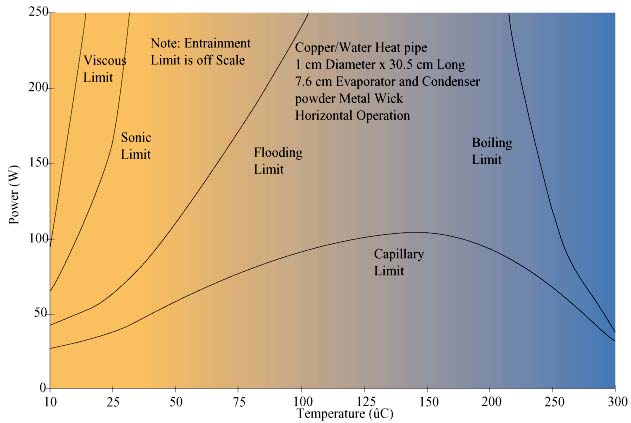

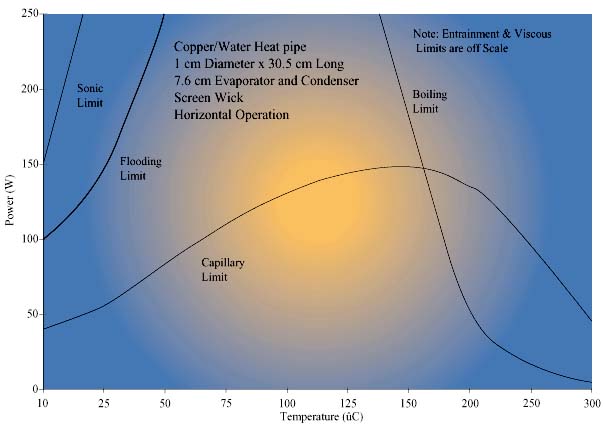

The maximum heat transport capability of the heat pipe is governed byseveral limiting factors which must be addressed when designing a heat pipe.There are five primary heat pipe heat transport limitations. These heattransport limits, which are a function of the heat pipe operating temperature,include: viscous, sonic, capillary pumping, entrainment or flooding, andboiling. Figures 2 and 3 show graphs of the axial heat transport limits as afunction of operating temperature for typical powder metal and screen wickedheat pipes. Each heat transport limitation is summarized in Table 1.

| Heat Transport Limit | Description | Cause | Potential Solution |

| Viscous | Viscous forces prevent vapor flow in the heat pipe | Heat pipe operating below recommended operating temperature | Increase heat pipe operating temperature or find alternativeworking fluid |

| Sonic | Vapor flow reaches sonic velocity when exiting heat pipeevaporator resulting in a constant heat pipe transport power and largetemperature gradients | Power/temperature combination, too much power at lowoperating temperature | This is typically only a problem at start-up. The heat pipewill carry a set power and the large ^T will self correct as the heat pipe warmsup |

| Entrainment/Flooding | High velocity vapor flow prevents condensate from returningto evaporator | Heat pipe operating above designed power input or at too lowan operating temperature | Increase vapor space diameter or operating temperature |

| Capillary | Sum of gravitational, liquid and vapor flow pressure dropsexceed the capillary pumping head of the heat pipe wick structure | Heat pipe input power exceeds the design heat transportcapacity of the heat pipe | Modify heat pipe wick structure design or reduce power input |

| Boiling | Film boiling in heat pipe evaporator typically initiates at5-10 W/cm2 for screen wicks and 20-30 W/cm2 for powdermetal wicks | High radial heat flux causes film boiling resulting in heatpipe dryout and large thermal resistances | Use a wick with a higher heat flux capacity or spread outthe heat load |

Table 1: Heat pipe heat transportlimitations

As shown in Figures 2 and 3, the capillary limit is usually the limitingfactor in a heat pipe design.

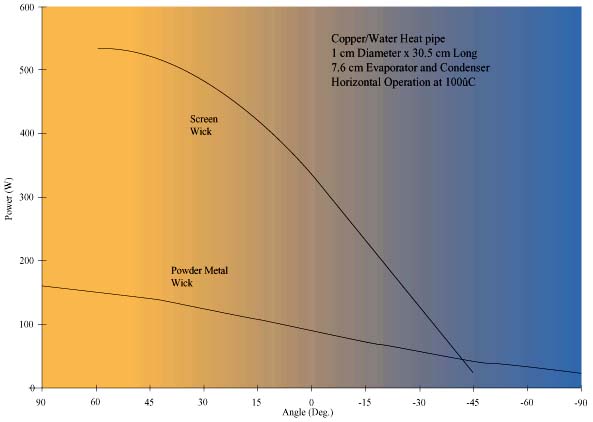

The capillary limit is set by the pumping capacity of the wick structure. As shown in Figure 4, the capillary limit is a strong function of the operatingorientation and the type of wick structure.

The two most important properties of a wick are the pore radius and thepermeability. The pore radius determines the pumping pressure the wick candevelop. The permeability determines the frictional losses of the fluid as itflows through the wick. There are several types of wick structures availableincluding: grooves, screen, cables/fibers, and sintered powder metal. Figure 5shows several heat pipe wick structures.

It is important to select the proper wick structure for your application.The above list is in order of decreasing permeability and decreasing poreradius.

Grooved wicks have a large pore radius and a high permeability, as a resultthe pressure losses are low but the pumping head is also low. Grooved wicks cantransfer high heat loads in a horizontal or gravity aided position, but cannottransfer large loads against gravity. The powder metal wicks on the oppositeend of the list have small pore radii and relatively low permeability. Powdermetal wicks are limited by pressure drops in the horizontal position but cantransfer large loads against gravity.

Effective Heat Pipe Thermal Resistance

The other primary heat pipe design consideration is the effective heat pipethermal resistance or overall heat pipeT at a given design power. As the heat pipe is a two-phase heat transfer device, a constant effectivethermal resistance value cannot be assigned. The effective thermal resistanceis not constant but a function of a large number of variables, such as heat pipegeometry, evaporator length, condenser length, wick structure, and workingfluid.

The total thermal resistance of a heat pipe is the sum of the resistancesdue to conduction through the wall, conduction through the wick, evaporation orboiling, axial vapor flow, condensation, and conduction losses back through thecondenser section wick and wall.

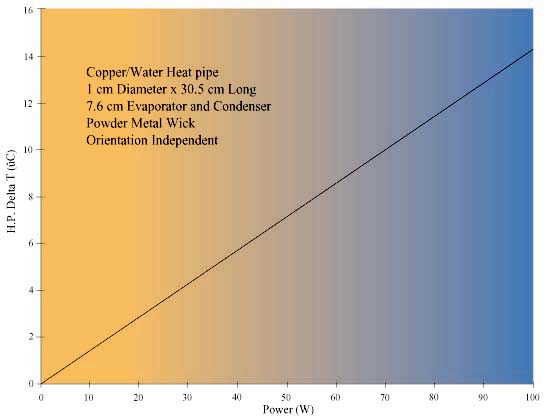

Figure 6 shows a power versusT curve for a typicalcopper/water heat pipe.

The detailed thermal analysis of heat pipes is rather complex. There are,however, a few rules of thumb that can be used for first pass designconsiderations. A rough guide for a copper/water heat pipe with a powder metalwick structure is to use 0.2°C/W/cm2 for thermal resistance at theevaporator and condenser, and 0.02°C/W/cm2 for axial resistance.

The evaporator and condenser resistances are based on the outer surface areaof the heat pipe. The axial resistance is based on the cross-sectional area ofthe vapor space. This design guide is only useful for powers at or below thedesign power for the given heat pipe.

For example, to calculate the effective thermal resistance for a 1.27 cmdiameter copper/water heat pipe 30.5 cm long with a 1 cm diameter vapor space,the following assumptions are made. Assume the heat pipe is dissipating 75 wattswith a 5 cm evaporator and a 5 cm condenser length. The evaporator heat flux(q) equals the power divided by the heat input area (q = Q/Aevap; q= 3.8 W/cm2). The axial heat flux equals the power divided by thecross sectional area of the vapor space (q=Q/Avapor; q = 95.5 W/cm2).

The temperature gradient equals the heat flux times the thermal resistance.

T = qevap* Revap + qaxial * Raxial + qcond* Rcond

T = 3.8 W/cm2* 0.2°C/W/cm2 + 95.5 W/cm2 * 0.02°C/W/cm2

+ 3.8 W/cm2 * 0.2°C/W/cm2

T = 3.4°C

It is important to note that the equations given above for thermalperformance are only rule of thumb guidelines. These guidelines should only beused to help determine if heat pipes will meet your cooling requirements, not asfinal design criteria. More detailed information on power limitations andpredicted heat pipe thermal resistances are given in the heat pipe design bookslisted in the reference section.

Heat Pipe Electronic Cooling Applications:

Perhaps the best way to demonstrate the heat pipes application toelectronics cooling is to present a few of the more common examples. Currently,one of the highest volume applications for heat pipes is cooling the Pentiumprocessors in notebook computers. Due to the limited space and power availablein notebook computers, heat pipes are ideally suited for cooling the high powerchips.

Fan assisted heat sinks require electrical power and reduce battery life.Standard metallic heat sinks capable of dissipating the heat load are too largeto be incorporated into the notebook package. Heat pipes, on the other hand,offer a high efficiency, passive, compact heat transfer solution. Three or fourmillimeter diameter heat pipes can effectively remove the high flux heat fromthe processor. The heat pipe spreads the heat load over a relatively large areaheat sink, where the heat flux is so low that it can be effectively dissipatedthrough the notebook case to ambient air. The heat sink can be the existingcomponents of the notebook, from Electro-Magnetic Interference (EMI) shieldingunder the key pad to metal structural components. Various configurations ofnotebook heat pipe heat sinks are shown in Figure 7.

Typical thermal resistances for these applications at six to eight watt heatloads are 4 – 6°C/watt. High power mainframe, mini-mainframe, server andworkstation chips may also employ heat pipe heat sinks. High end chipsdissipating up to 100 watts are outside the capabilities of conventional heatsinks. Heat pipes are used to transfer heat from the chip to a fin stack largeenough to convect the heat to the supplied air stream. The heat pipeisothermalizes the fins eliminating the large conductive losses associated withstandard sinks. The heat pipe heat sinks, shown in Figure 8, dissipate loads inthe 75 to 100 watt range with resistances from 0.2 to 0.4°C/watt, dependingon the available air flow.

In addition, other high power electronics including Silicon ControlledRectifiers (SCR’s), Insulated Gate Bipolar Transistors (IGBT’s) and Thyristors,often utilize heat pipe heat sinks. Heat pipe heat sinks similar to the oneshown in Figure 9, are capable of cooling several devices with total heat loadsup to 5 kW. These heat sinks are also available in an electrically isolatedversions where the fin stack can be at ground potential with the evaporatoroperating at the device potentials of up to 10 kV. Typical thermal resistancesfor the high power heat sinks range from 0.05 to 0.1°C/watt. Again, theresistance is predominately controlled by the available fin volume and air flow.

Scott D. Garner P.E.

Thermacore Inc., 780 Eden Road,

Lancaster PA17601 USA

Tel : +1 (717) 569-6551

Fax:+1 (717) 569-4797

Email: garner@thermacore.com

References

1. Brennan, P.J. and Kroliczek, E.J., Heat PipeDesign Handbook, B&K Engineering, NASA Contract No. NAS5-23406, June 1979.

2. Chi, S.W., Heat Pipe Theory and Practice, Hemisphere PublishingCorporation, 1976.

3. Dunn, P.D. and Reay, D.A., Heat Pipes, 3rd. Edition, Permagon Press,1982.

4. Eastman, G. Yale and Ernst D.M., Heat Transfer Technology (Heat Pipe), Kirk-Othmer: Encyclopedia of Chemical Technology, Volume 12, John Wiley andSons, Inc., 1980.

5. Peterson, G.P., An Introduction to Heat Pipes Modeling, Testing, andApplications, John Wiley and Sons, Inc., 1994.