Thermoelectric temperature control systems are being used in an increasingnumber of applications. Typical applications of these systems are in thermalregulation of electronic enclosures, recirculating chillers for laser cooling,semiconductor process control and management of patient hypo- and hyperthermia.

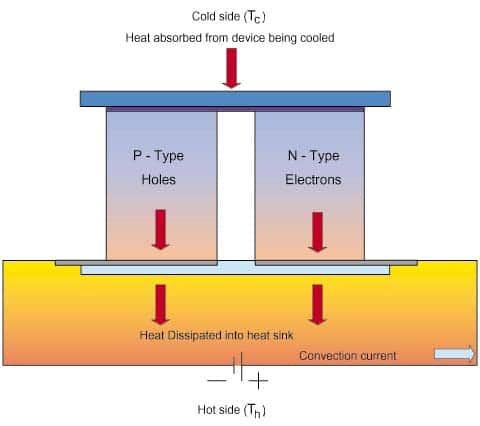

Thermoelectric coolers (TECs) are essentially solid state devices that pumpheat against a temperature differential utilizing electrical energy. Based onthe Peltier effect, each cooler consists of a matrix of thermoelectric p-nthermocouples connected electrically in series (Figure 1) and thermally inparallel. A cross section of a thermoelectric cooler is shown in Figure 1.

Figure 1: A cross section of athermoelectric cooler

When positive DC voltage is applied, holes pass from the p-type to then-type thermoelement and the cold side temperature (Tc) decreaseswhile heat is absorbed. Reversing the direction of current results in heatinginstead of cooling and this is a significant advantage of thermoelectriccoolers. Several thermoelectric coolers can be configured with common hot andcold sides to make up a thermoelectric heat exchanger. Efficient heat removalsfrom the hot and cold sides is a must for good efficiency.

A significant disadvantage of using thermoelectric systems for coolingelectronic enclosures has been the dismal level of efficiency. The bestthermoelectric systems can only provide around a 35% efficiency rating. However,depending on the application, thermoelectric temperature control systems can begiven preference, if size and reliability are the issue.

Bellcore[1] specifies that in a 50°C environment, the enclosuretemperature cannot exceed 65°C. A passive system would be too large toaccommodate such heat removal with only a 15°C rise. A compressor systemcan handle this heat load but will not provide any cooling under an AC line lossscenario. However, a thermoelectric system can provide adequate heat removalwith a 15°C rise or even a 10°C differential in a more effectivemanner with DC capabilities.

There are numerous advantages to using thermoelectric temperature controlsystems. Tabulated below is a comparison chart between a TEC system andcompressor system.

| Factor | TEC Systems | Compressor Systems |

| Size | Small | Large |

| Reliability: Thermoelectrics vs. Compressors | >100,000 Hours [2] under continuous operation | < 40,000 Hours |

| Maintenance | Low | High |

| Cost | Comparable | Comparable |

| Chemicals | None | CFC, HCFC |

| Temperature control | Precise bipolar control | Inefficient resistive control |

| Stability | < +/- 0.05 °C | > +/- 1.0 °C |

| Frequency | DC, 50, 60, 400 Hz | 50, 60 Hz |

Roger DeVilbiss and Sathya Rajasubramanian

ThermoTek, Inc., 1454Halsey Way, Carrollton, TX – 75007, USA.

Tel: +1 (214) 242 3232 Fax: +1(214) 446 1195

References

1. Marlow Industries, Inc., “Reliability ofThermoelectric Coolers”.

2. Bell Communications Research; “Generic Requirements for ElectronicEquipment Cabinets”, TA-NWT-000487; Issue 2; June, 1993.