Introduction

Telecommunication satellites are all based on the same overall design usinga 3 axis stabilization process, in which the North and South panels act asradiators and so ensure heat removal.

This basic principle is illustrated in Figure 1. The ever-increasing demandfor national and international space-based communications in parallel with theevolution of space electronics (miniaturization, complexity, integration)dictate that the thermal control subsystem (TCS) can accommodate significantincreases in spacecraft dimensions and waste heat generation. At the same time,for obvious economic reasons, the operational life time in orbit has to reach 15years for most satellite programs.

Requirements and Design Goals

Methodology

Space programs, generally limited to very few models characterized by highcost (typically $50,000-100,000/Kg), must follow a specific methodology. Themain design features of this methodology are:

- The TCS design has traditionally been a conservative process. Use ofpreviously flown materials, technology and concepts is encouraged.

- The design is mainly based on an important use of analytical models (seeFigure 2). The simulation is achieved by using CAD software (CATIA) as a meshgenerator and ESATAN (European Agency Thermal Analysis) as a thermal solver.Mock up and thermal tests are considered for final verification.

- Assumptions obtained by thermal modeling are a possible source of errors,thus uncertainty margins (typically ±5°C) are taken into account bythermal designers in order to make “guaranteed predictions”.

Electronic Equipment Temperature Limits and Design

A spacecraft contains many components which will function properly only ifthey are maintained within specified temperature ranges. Figure 3 illustrates aclassical set of temperature limits for on board equipment.

| EQUIPMENT | ON-ORBIT TEMPERATURE RANGE (°C) | QUALIFICATION RANGE (°C) | ||||

| Minimum during non operating phase | Operating | Operating | ||||

| Electronic Units | MIN | MAX | MIN | MAX | ||

| “ | TWT (traveling wave tubes) | -30 | 0 | +75 | -10 | +85 |

| “ | Electronic power conditioner | -30 | 0 | +50 | -10 | +60 |

| “ | Input filters | -30 | +5 | +50 | -5 | +60 |

| “ | Microwave equipment (transponders, receivers, ….) | -30 | -10 | +50 | -20 | +60 |

| “ | Output multiplexers | -30 | +20 | 70 | +10 | +80 |

| “ | Data processing units | -30 | -10 | +50 | -20 | +60 |

| “ | IR and sun sensors | -45 | -30 | +50 | -40 | +60 |

| “ | Battery Ni-H2 | -20 | -5 | +25 | -15 | +35 |

| Non-electronic units | Tanks | 0 | 0 | 40 | -10 | 50 |

| Solar generator | -180 | -165 | +70 | -175 | +80 | |

| Propellant lines | 0 | 05 | 0 | -10 | +60 | |

| Momentum wheels | -40 | -15 | 45 | -25 | +55 | |

Figure 3 – Temperature limits for on-boardequipment

In order to meet the challenge of the increasing complexity of communicationsatellite payloads, the packaging of space electronic equipment must minimizethe imposition of severe constraints on electronic designers.

From a reliability point of view, the fundamental goal of TCS is to ensure amaximum junction temperature of 110°C; therefore, Printed Circuit Boardswith high thermal conductivity are used in conjunction with local heatspreaders. In some critical areas, heat pipes are used to provide efficient andlow mass technical solutions.

An overall view of the implementation of electronic equipment inside atelecommunication satellite is illustrated in Figure 4.

Spacecraft Thermal Control Subsystem Description

Radiators

The radiators use primary heat rejection surfaces:

- they support high dissipating electronic units (traveling wave tubes andconverters). The structural composition of these panels is generally aluminumface sheet and honeycomb core.

- they are designed for a maximum thermal efficiency achieved by usingembedded heat pipes in association with a specific coating providing a highinfrared emittance with a low solar absorptance (so called Optical SolarReflectors). For end of life conditions, heat rejection capability may reach upto 350 W/m2 for a typical 40°C radiator temperature.

A concept of a flexible radiator, acting as a ‘thermal diode’, which allowsheat to pass from an internal to external side has been designed andsuccessfully qualified by Alcatel Espace to reduce TCS weight for low earthorbit missions.

Heat Pipes

The vast majority of heat-pipe applications use an axially groovedaluminum/ammonia Constant Conductance Heat Pipe (CCHP) (See Figure 5).Successful ground testing and flight experiences indicate CCHP to be a reliablethermal control element.

Non condensable gas generation caused by impurities is controllable by themanufacturers process.

Liquid slug formation in zero gravity still remains a problem and is takeninto account during CCHP layout on the spacecraft panels.

Insulation Design

With the exception of the radiator areas used for heat rejection, asatellite is covered by a blanket of Multi Layer Insulation (MLI) intended forprotection from solar flux and to protect surfaces submitted to large diurnalenvironmental fluctuations -180°C up to +150°C.

MLI design consists basically of a number of layers of vapor-depositedaluminum, silver or gold on Kapton or Mylar. Conductive insulation betweenlayers is insured by interleaved fabric netting.

Another important requirement for MLI design is to provide an efficientprotection against Electro Static Discharge (ESD), which may appear betweenseparated parts when formed from different materials or submitted to sunlight orshadow.

Heaters

Thermal control of electronic equipment within a narrow range of temperature(ambient ±20°C), with external surface temperature differences rangingfrom -180°C up to + 150°C, is generally achieved with the help ofactive heaters controlled by mechanical thermostats or on-board computers.Heating elements are generally thermofoil conductive electrical elementsembedded in a thin Kapton substrate.

Solar Simulation

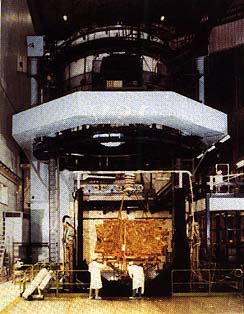

A thermal vacuum test environment with solar simulation is essential forverification of the thermal mathematical models and TCS performances in asimulated orbital environment.

Solar heat fluxes are simulated by a set of Xenon lamps which illuminate theSpacecraft by focusing into a single collimated beam.

These huge test facilities are only available in a few locations in theworld: Interspace in Toulouse has a facility (see Figure 6), which includesother environmental tests (mechanical, EMC), thus permitting a certification of”flight aptitude” for spacecraft before launch.

Conclusion

The continued strong growth in communication satellite requirements hasresulted in a need for more complex satellites which must be delivered in theshortest time possible.

TCS designers will be required to enhance flight-proven technologies, whiledeveloping new techniques such as fluid loops and micro heat-pipes.

Patrick Zemlianoy

Head of Design for Space Environment and Methodology

AlcatelEspace, 26, avenue J.F. Champollion, B.P. 1187

31037 Toulouse Cedex, France

Tel: +33 61 19 57 25 Fax: +33 61 19 59 20

Email: frdk86Z8@ibmmail.com

Charles Combes

Manager, Thermal Design Office, Alcatel Espace

26,avenue J.F. Champollion, B.P. 1187, 31037 Toulouse Cedex, France

Tel: +3361 19 57 19 Fax: +33 61 19 59 20

References

1 Techniques et technologies des v hicules spatiaux(CNES), Cepadues Satellite Communication System Engineering, W.L .Pritchard,J.A. Sciulli, Prentice Hall.

2 Thermal Analysis and Control of Electronic Equipment, A.D. Krauss, A. Bar-Cohen, McGraw-Hill.