A very large factor in reducing thermal interface resistance is theapplication of pressure. Even though much effort in recent years has beendevoted to improving the thermal conductivity of interface materials, thethermal conductivity of a material is only a piece of the heat transfer puzzle.

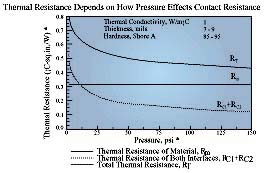

As shown in Figure 1, the thermal resistance created by the material itself(RM) for a given thickness is constant as a function of pressure;whereas the contact thermal resistances at the interfaces (RC1 + RC2)are very dependent on pressure. At low pressures of <15 psi the contactthermal resistances can account for more than 50% of the total thermalresistance (RT) of a typical interface material as described inFigure 1.

Figure 1

Therefore the total thermal resistance (RT) is the sum of threeresistances:

| RT = RC1 + RM + RC2 |

| RT = Total Thermal Resistance |

| RC1 = Contact thermal resistance of surface 1 |

| RM = Thermal Resistance of the material itself (thickness÷thermalconductivity for a given area)1 |

| RC2 = Contact thermal resistance of surface 2 |

Pressure acts to mate the interface material to its surfaces, minimizing theamount of air remaining at the interface, therefore decreasing the thermalresistance. Air, the number one enemy to reducing contact resistance, is trulya thermal insulator with a thermal conductivity of 0.027W/m°C. Increasingpressure not only reduces the thermal contact resistance, but can reduce RMof soft materials by reducing the material thickness.

The amount of pressure required to reduce thermal resistance is a functionof the interface material’s compressibility and surface properties. The surfaceproperties of the mating surfaces are also a factor.

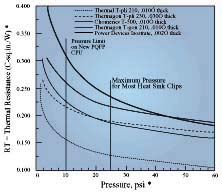

In today’s electronic systems the use of excessive pressure can createstresses detrimental to a system. For example, delicate leads and solder jointscan be broken and circuit boards can lose their planarity from excessivepressure. In most cases pressure over 50 psi is damaging. Often 10 psi is allthat can be tolerated. Therefore, the need for very soft, compliant materialswith high thermal conductivities are essential for low total thermal resistanceat low pressures. Figure 2 shows the thermal resistance versus pressure forinsulating interface materials with a thermal resistance of 0.20°C-in2/Wor less at 50 psi.

Figure 2

Unfortunately the pressure used to acquire reported thermal resistancevalues is often not stated by vendors. The values reported are often measuredat pressures well in excess of 100 psi, much higher than would be practical inreal applications. An international standard for characterizing interfacematerials is definitely needed.

* 1 sq. in. = 6.45 sq. cm. 1 psi = 0.0069 Mpa

1 Steinberg, Dave S., Cooling Techniques for ElectronicEquipment p.48, 1980.

Carol A. Latham

Thermagon, Inc., 3256 West 25th Street, Cleveland, Ohio44109

Phone: +1 (216) 741-7659 Fax: +1 (216) 741-3943