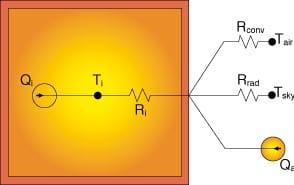

Figure 1. Thermal analog model of an OSP enclosure

Introduction

Over the past twenty years, telecommunications electronics have become increasingly decentralized – moving ever furtherfrom the controlled and protected environment of the Central Office intothe Outside Plant (OSP). The OSP environment contains rain and humidity,dust and pollutants, significant daily and annual temperature swings, widesolar heat-load variations, and physical abuse. To protect electronicsfrom this hostile environment, they are housed in a variety of OSPenclosures, which can range from small buildings (30 m3) to small boxes (3×10-3 m3) that are mounted on the homes of customers.Heat densities within OSP enclosures can be large, often rivaling those of electronics designed for controlled indoor environments. Thecombination of OSP environment and high heat density means that thetelecommunications OSP thermal designer must be equally familiar withbroad HVAC (heating, ventilation and air conditioning) techniques anddetailed electronic thermal-management technologies. In addition, becausethe enclosures are located in business and residential neighborhoodsremote from central maintenance facilities, the designer must take intoaccount community restrictions on size, noise (e.g., from ventilationfans) and “aesthetics” and human factors that affect theaccessibility and maintainability of the enclosure equipment.

Enclosure temperature

Figure 1, a much simplified analogmodel of an OSP enclosure, shows the major factors that control theinternal temperature Ti of theenclosure. These include the enclosure heat sources, heat sinks, coolingmethod and the thermal parameters of the enclosure:

| Ti = Qi [Ri+Ro] + Q |

Equation 1 |

| l/Ro = l/Rconv + l/Rrad |

Heat sources in the enclosure are Qi, the heat generated by the internal equipment, and Q, the solarenergy (“insolation”) that is absorbed and transmitted into theenclosure. The two primary heat sinks are the local ambient air attemperature Tair and the remote “sky” at temperature Tsky. As indicated in Equation 1, heat is transferred to the local air primarily by convection and to the remote sky by radiation. The internal thermal resistance, Ri, is determined primarily by the cooling method,while the thermal parameters affect the internal and external resistances,Ri and Ro,and the fraction of incident solar energy that is absorbed into theenclosure.

Heat sources and sinks.

Internal heat generation, Qi: Probably one of the moste effective actionsthat can be taken to reduce internal temperatures in an OSP enclosure isto reduce its internal heat genereation. This is due, in part, to thedirect relationship between these two quantities indicated in Equation 1.In addition, OSP electronics are typically powered remotely – and severalredundant powering systems are employed to ensure uninterruptedtelecommunications service. Each powering system exhibits an inefficiency,and these inefficiencies translate into added heat load within theenclosure. A typical example is an OSP electronic system whose primarypower is provided by the local electric utility system and whose secondary(backup) power is provided by batteries housed in the enclosure. Both thepower conditioning used to convert utility power to the low voltagesneeded by the electronics and the battery charging can add significantinternal heat to the enclosure. One additional incentive for keepinginternal heat generation low is that larger heat loads generally requiremore “active” cooling systems; the power and primary/redundantpower inefficiencies needed to operate these systems add, once again, tothe heat in the enclosure.

Solar heat load, Q: A second source of heat in an OSP enclosureis the solar energy that is absorbed and transmitted into the enclosure:

| Q |

Equation 2 |

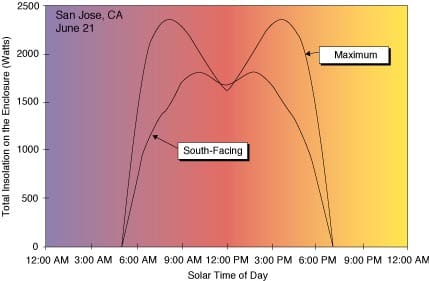

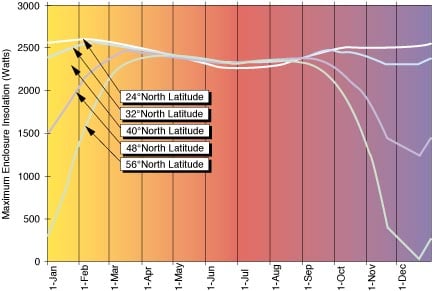

In Equation 2, Qsun is the totalshortwave radiation from the sun (insolation) that falls on the enclosureand solis the solar (shortwave) absorptance of the enclosure surfaces. The totalinsolation includes direct shortwave radiation from the sun, diffuseshortwave radiation that has been scattered by the atmosphere, and anyshortwave radiation that is reflected from the ground or nearby surfaces.It is a complicated function of the orientation of the enclosure withrespect to the earth-sun line, the amount of moisture, dust andcontaminants in the air, and the solar reflectivity and location of nearbysurfaces (e.g., landscaping, fences and buildings). Procedures forcalculating Qsun for an enclosure witha known location and orientation are well documented. (See, for example,References 1 and 2.)Bellcore specifies that OSP enclosures must be designed for ubiquitousOSP use and must handle the maximum solar load at the maximum ambient airtemperature and the maximum internal heat load[3]. Determining maximum solar load is not simple when the enclosure location and orientation are unknown. Figure 2 shows the total insolation incident on a 60cm (deep)x120cm (wide)x180cm (high) (2ftx4ftx6ft) enclosure located in a low-reflecting open field environment (i.e., no surroundingreflecting surfaces). The lower curve in Figure 2a shows the totalinsolation for San Jose, CA for June 21 for a specific enclosureorientation: front surface facing due south. The upper curve shows themaximum insolation for the same location and date: imagine an enclosurethat is continuously rotated to capture the maximum sun. Figure 2b showsthe maximum insolation at 3PM (the approximate time that the maximum airtemperature occurs) for various North American latitudes. For this case,the maximum insolation is over 2600 Watts at a latitude of 24°N.

Figure 2a: total solar energy incident on a 60cm x 180cmOSP enclosure.

Most enclosures are not located in open-field environments, but innormal communities surrounded by landscaping, fences and buildings. Oftenthese surroundings will shade the enclosure and hence reduce the solarload. Equally often, the surroundings will reflect additional sunshineonto the enclosure and increase the load. The maximum insolation on the60cmX120cmX180cm enclosureincreases by a factor of 1.3 when it is located near a large light-colored(reflecting) building and by 1.4 when it is located in a three-sided,reflecting fence alcove. As discussed below, either of these locations maybe chosen to make the enclosure less obtrusive.

The second parameter in Equation 2 that affects the solar load absorbed into the enclosure is sol, the shortwave absorptance of the enclosuresurface. Table 1 shows representative values for this parameter forseveral common enclosure surface treatments. Also shown are longwaveemittances for the surfaces. Both parameters must be considered inenclosure design: the shortwave absorptance controls the fraction ofincident solar heat absorbed into the enclosure, and the longwaveemittance controls the heat that is dissipated by radiation to thesurroundings. This is illustrated in an example discussed below.

| SURFACE | Shortwave (solar) absorptance |

Longwave emittance |

| Polished Aluminum | 0.03 | 0.05 |

| Oil-Based Paints: | ||

| White | 0.20 | 0.90 |

| Light Green | 0.50 | 0.90 |

| Light Gray | 0.75 | 0.90 |

Table 1. Radiative propertiesof typical OSPenclosure surfaces

Local ambient air temperature, Tair: The major heat sink for the heat dissipated from the enclosure is the local ambient air. The temperature of this sink varies widely withlocation, time of year, and time of day. For OSP enclosures intended foruse throughout North America, Bellcore specifies an ambient airtemperature range of -40°C to + 46°C (-40°F to + 115°F)[3].Remote sky temperature, Tsky: A secondary heat sink, which is often neglected in enclosure design, isthe “remote sky”. Hot surfaces radiate heat continuously inproportion to the fourth power of their absolute temperature(Stefan-Boltzman Law); the net heat radiated depends on the longwaveemissivity of the surface ó and on the emissivities andtemperatures of the surroundings. Since the atmosphere is generally coolerthan the enclosure and any nearby terrestrial surfaces, it can be a veryeffective heat sink.For an enclosure in an open-field environment, the atmospheric can bemodeled by an “apparent sky temperature”, defined as thetemperature of a black body (i.e., perfect radiator) that emits radiationat the same rate as the atmosphere; the sky temperature can be estimatedfrom local weather conditions (dew point and dry bulb temperatures)[2]. Sky temperature is always lower than ambientair temperature, especially when the air contains little water vapor: thisis the reason that frost occurs on terrestrial surfaces even when the airtemperature is well above freezing.

The atmosphere/remote sky is most effective as a radiant heat sinkduring the spring and fall, when dew point and dry-bulb temperatures arerelatively low, and in dry dessert climates. It is not effective underovercast conditions or summer conditions of high dew point/dry bulbtemperatures. On account of this, conservative design techniques should beused and the sky temperature should be assumed to be equal to the localambient air temperature. (Note: if an enclosure is tested during dry,clear climate conditions, the additional radiation heat loss to the skyshould be factored out of the results to get a clearer picture of how theenclosure will perform under more normal OSP conditions.)

Enclosure cooling

A large variety of cooling techniques have been proposed and used to cool OSP electronics equipment enclosures. These include conventional techniques, ranging from passive natural convectionto the use of commercial air conditioners or heat pumps, and nov novelconcepts using thermosyphon and PCM (Phase Change Material) technologies.Many of these techniques have been presented at annual INTELEC Conferences(International Telecommunications Energy Conference)[4].The most common cooling method used today in the OSP is relativelysimple. The enclosure is unventilated to protect the internal equipmentfrom the rain, dust, and contaminants in the outside air. The internalheat is transferred primarily by convection to the inside surfaces of theenclosure, by conduction through the walls of the enclosure, and then byconvection and radiation to the external heat sinks. Reference 5 presentsa first-level model for estimating internal temperatures in suchenclosures, including methods for estimating the external resistances inEquation 1: Rconv, the wind-inducedconvective resistance to the ambient air, and Rrad, the radiative resistance to local and remote surroundings. The interior resistance, Ri, depends on the type of convection used (free and/or fan-forced) and the interior electronicscharacteristics; normal electronic thermal-management techniques can beused to determine this. (See, for example, Reference 6).

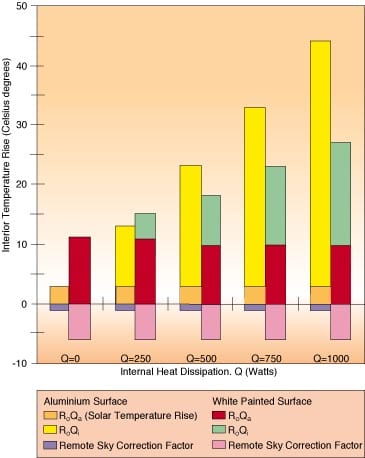

Figure 3. Contributions to enclosure internaltemperature rise

Figure 3 shows typical internal temperature rises from several factorsfor an unventilated 60cmX120cmX180cm enclosure located in an open field environment. Two enclosure surfaces are depicted: an unpainted aluminum and a white-painted surface. The factors in the figure may best be understood by rewriting Equation 1 as:

Ti – Tair = RiQi + RoQi + RoQ – [Ro/Rrad][Tair – Tsky]The first factor, Ri Qi, is not shown in the figure: the cooling methodwill be dictated by the difference between equipment design constraints onTi and the temperature rises from theremaining factors. The exterior resistances, Rconvand Rrad, were estimated using thefirst-level models in Reference 5, assuming low wind velocities andradiation parameters from Table 1. Enclosure insolation was assumed to be2600 Watts, as detailed in Figure 2b; thus the solar load Q

was 80 Watts and 650 Wattsfor the aluminum and white-painted surfaces, respectively. The skycorrection factor, [Ro/Rrad][Tair – Tsky], was estimated using ASHRAE summer designconditions for San Jose, CA: 29oC drybulb and 19oC wet bulb. For theseconditions, the remote sky temperature is 17oC-12oC lower than the local ambient air.As shown in Figure 3, there is a temperature rise in the enclosure from the solar load even when there is no internal load. Here the advantages of minimizing shortwave absorptance follows intuition: reducing the amount of insolation absorbed reduces the solar temperature rise. As the internalheat generation increases, however, removing the heat from the enclosurebecomes critical. Here, the advantage of increasing longwave emittance,even at the expense of increasing solar load becomes apparent.

Other issues: Besides the normal issues (e.g., equipmenttemperature limitations and heat load) that must be addressed in selectinga cooling system, there are issues unique to the OSP environment. Theseinclude power availability and the cooling system power requirements,required frequency and ease of maintaining the system, reliability of thesystem in the harsh OSP environment (and the effect on other equipment ifthe cooling system fails), and community restrictions/guidelines on noiseand aesthetics. All of these issues should be addressed in relation toequivalent issues with the other equipment in the enclosure. For example,filters that require frequent maintenance should not be used in remote OSPenclosures – unless other equipment in the enclosure also requiresfrequent and regular maintenance; if it does, circulation of filteredambient air may be an effective cooling method. Two issues thatparticularly effect cooling design are increasingly stringent communityrestrictions on noise and aesthetics.

Noise restrictions: Several potential cooling methods generatenoise, e.g., convection-enhancing fans. Communities are beginning torecognize noise as a form of environmental hazard and to impose noiserestrictions on equipment located in the communities. Generally, theserestrictions depend on the “land use zone”, e.g., restrictionsfor hospital and library zones are generally stricter than for industrialparks. Bellcore currently specifies a maximum noise level of 60 dBA forenclosures[3]. This level is probablytoo high, since the Environmental Protection Agency has identified 55 Ldn (average day/night noise level) as thedesirable maximum level for outdoor noise[7].Aesthetics: Measures are often taken to hide or to obscure anenclosure in order to gain neighborhood approval/acceptance and to reducethe likelihood of graffiti and vandalism. Examples include planting andlandscaping around the enclosure, painting it to match its surroundings,placing it near like-colored walls or fences, recessing it into fence/wallpockets or alcoves, and completely fencing it. Each of these measurescould increase the internal temperature (e.g., by increasing the solarload or reducing the effective heat transfer), and must be considered inthe enclosure design.

| Nomenclature | |

| Q1 | heat generated by equipment inside the enclosure |

| Qsun | total solar (shortwave) radiation incident on the enclosure |

| Q |

solar heat absorbed into the enclosure Q |

| Rconv | wind-induced convective thermal resistance from exterior surfaces of enclosure |

| Ri | thermal resistance from interior to exterior surfaces of enclosure |

| Ro | thermal resistance from enclosure exterior surfaces to external heat sinks, 1/Ro=1/Rconv+1/Rrad |

| Rrad | radiative thermal resistance from exterior surfaces of enclosure |

| Tair | temperature of local embient air |

| Ti | temperature inside enclosure |

| Tsky | temperature of atmosphere above enclosure |

| solar (shortwave) absorptance of enclosure surface | |

References

| 1. | ASHRAE Handbook & Product Directory – 1977 Fundamentals, Atlanta, GA: ASHRAE, Inc., 1977, Ch 26. |

| 2. | HVAC Systems and Applications – 1987 ASHRAE Handbook, Atlanta, GA: ASHRAE, Inc., 1987, Ch 47. |

| 3. | Bellcore TA-NWT-000487, Generic Requirements for Electronic Equipment Cabinets, Issue 2, June 1993. |

| 4. | INTELEC Proceedings are available from the IEEE, New York. |

| 5. | Coyne, J.C., “An Approximate Thermal Model for Outdoor Electronics Cabinets”, The Bell System Technical Journal, Vol 61, February, 1982. |

| 6. | Kraus, Allan D. and Bar-Cohen, Avram, Thermal Analysis and Control of Electronic Equipment, New York: Hemisphere Publishing, 1983. |

| 7. | Cowan, James P., Handbook of Environmental Acoustics, New York, NY: Van Nostrand Reinhold, 1994. |