One of the primary tasks of the thermal engineer is to determine the temperature of the junction (active circuitry on an integrated circuit) for the various packages in a system. Measurements performed in the industry-standard test environment are often used in this endeavor. The most common thermal metric [1,2] is the junction-to-air thermal resistance, ![]() JA (pronounced theta, ja) determined from the following equation

JA (pronounced theta, ja) determined from the following equation

![]()

where TJ is the junction temperature, TA is the temperature of the ambient air, and P is the total power dissipated by the device. This thermal metric is measured under standard, but artificial conditions. It is useful for comparing the thermal performance of various packages but often has limited relevance in determining TJ in the application.

For situations in which an actual system exists, TJ can be determined by a measurement of the temperature on the top center of the package, TT, and the use of a more recently defined metric,![]() JT.

JT.

![]() JT (pronounced psi, jt), or the junction-to-top thermal characterization parameter [1,2], is determined by taking a measurement in an industry-standard test environment and inputting the results into the following equation:

JT (pronounced psi, jt), or the junction-to-top thermal characterization parameter [1,2], is determined by taking a measurement in an industry-standard test environment and inputting the results into the following equation:

![]()

The measurement should be performed with the same package used in the system, with approximately the same size die, and on a board with the same stackup (number of signal layers and power/ground planes). This equation has the same form as a thermal resistance calculation, but is not a true thermal resistance since the total power is used in the calculation and not the power flowing from the junction to the top of the package.

When used to calculate TJ in the application, this equation is rearranged as follows

with TT and P determined from the system environment.

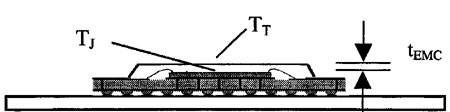

Although useful, ![]() JT, is not yet commonly measured. However, it can be estimated for a package constructed with epoxy molding compound (EMC) above the die as shown in the figure, using a measured value of

JT, is not yet commonly measured. However, it can be estimated for a package constructed with epoxy molding compound (EMC) above the die as shown in the figure, using a measured value of ![]() JA in the following equation

JA in the following equation

where h is the heat transfer coefficient.[3], and tEMC and EMC are the thickness and thermal conductivity of the EMC, respectively. The expression for

![]() JT is derived assuming that TT-TA~TJ– TA. The physical basis for this equation is that the temperature difference between the junction and the package top is dependent upon the amount of heat flowing out of the top of the package, as determined by the magnitude of h.

JT is derived assuming that TT-TA~TJ– TA. The physical basis for this equation is that the temperature difference between the junction and the package top is dependent upon the amount of heat flowing out of the top of the package, as determined by the magnitude of h.

The following table displays values of ![]() JT calculated for a PBGA (Plastic Ball Grid Array) package of the sort illustrated in the figure. In these calculations, tEMC and

JT calculated for a PBGA (Plastic Ball Grid Array) package of the sort illustrated in the figure. In these calculations, tEMC and EMC are assumed to be 0.85 mm and 0.7 W/mK, respectively.

|

Note that the calculated values of ![]() JT increase as more heat is preferentially extracted out of the top of the package with increasing air velocity.

JT increase as more heat is preferentially extracted out of the top of the package with increasing air velocity.

References

1. JEDEC Standard, “Integrated Circuits Thermal Test Method Environment Conditions – Natural Convection (Still Air),” EIA/JESD51-2.

2. JEDEC Standard, “Integrated Circuits Thermal Test Method Environmental Conditions – Forced Convection (Moving Air),” EIA/JESD51-6.

3. See Calculation Corner, Electronics Cooling Magazine, January, 1998, “Convection and Radiation,” for a graph used to estimate h at various air velocities.