It’s no news to any of the readers of this publication that the increased power dissipation of integrated circuits has led to continuous refinement of package designs and component materials. This trend has increased the importance of thermal interface materials (TIMs) as a key factor in determining the thermal performance of packages intended for high-power applications. This increased importance of TIMs necessitates the use of more precise methods for determining their impact on the package thermal resistance.

Physical Picture

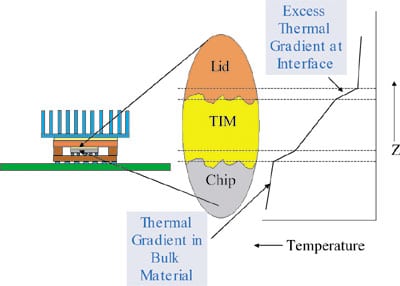

Figure 1 illustrates a typical method of packaging a high-power IC chip. In this example, the device is a flip chip with a solder bump array providing the electrical interconnection to the package substrate. The heat-generating circuitry is on the lower surface of the chip. The heat is routed out of the back of the chip – first to the package lid and then to a heat sink mounted to the top of the package. In this example, there are two TIMs: 1) joining the chip to the lid, and 2) joining the lid to the heatsink.

|

Figure 1. TIM application. Effect of bulk and interfacial thermal properties of TIM on thermal performance.

TIMs may be either low modulus materials, such as greases, gels, or phase-change materials, or higher modulus adhesives. A key function of a TIM is to provide efficient, stable, and uniform thermal coupling between two surfaces in spite of any warpage or surface roughness.

The inset in Figure 1 illustrates the microscopically rough nature of surfaces on typical packaging components. TIMs are designed to conform to the contours of the surfaces, which contact them. However, with the materials in commercial use today, there will always be an excess thermal resistance within the interface region. This results from factors such as incomplete wetting of the surface by the TIM or the exclusion of the particulate filler materials from the interfacial region.

The graph in Figure 1 illustrates the thermal gradients both within the bulk material and at the interface, assuming a 1-D heat flow situation. The temperature within the bulk materials decreases linearly with increased distance from the heat source. The gradient is simply related to the heat flux and the bulk thermal conductivity of each of the materials. However, in the interface regions bounding the TIM, there is an abrupt change in temperature. This excess thermal gradient at the interface depends upon the surface chemistry of materials adjoining the TIM and the method of application of the TIM, among other factors. Hence, it is not an intrinsic property of the TIM, but, rather, depends upon the details of the application.

Mathematical Representation

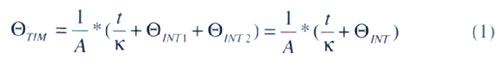

Assuming a 1-D heat flow, the thermal resistance of a TIM, including the two interfacial regions, is calculated from

|

where A is the cross-sectional area of the TIM, t is its thickness (commonly referred to as the bond line thickness or BLT), is its bulk thermal conductivity,

INT1 and

INT2 are the values of interfacial thermal resistance for unit area at each of the interfaces [1].

INT lumps both interfacial thermal resistances into a single value.

INT is represented in metric units as cm2°C/W. Equation 1 indicates that

TIM is a linear function of the BLT, with a slope equal to 1/(A

) and a y-intercept equal to

INT/A.

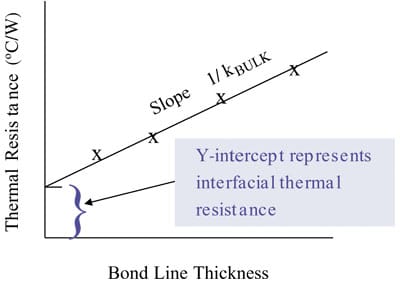

Figure 2 illustrates the use of Equation 1. When TIM is measured using a series of test coupons with various TIM thicknesses, a line can be fitted to the resultant data.

and

INT can then be determined directly from the slope and intercept.

|

Figure 2. TIM thermal resistance versus bond line thickness.

Cautionary Notes

Note 1. Performing a series of measurements to extract the slope and intercept of TIM versus BLT can represent a significant effort. It is sometimes expedient to perform a measurement at one BLT value only. The equation

TIM = t/A

EFF is solved to yield a value of

EFF (effective value of thermal conductivity).

EFF can be used to calculate the temperature difference across a TIM with full accuracy only at the thickness at which it was measured. If

EFF is used in calculations for the same TIM but at another value of BLT, significant error may result.

Note 2. TIM manufacturers who follow the established ASTM procedure will report only for a particular material and not

INT [2]. Their rationale is that, unlike

,

INT can vary from application to application, and, hence, they have limited control over it. It is their policy to report on the properties that they have full control over and can be incorporated into specifications for the TIMs.

The ASTM procedure used to extract is essentially that illustrated in Figure 2. As such it is rigorous, unlike the

EFF method. Unfortunately, unless an appropriate value of

INT can be included in TIM thermal calculations, considerable error may result, particularly at small values of BLT.

Conclusions

It is a straightforward procedure to calculate the thermal performance of a TIM as long as INT is properly accounted for. The biggest challenge can often be getting the correct values of

and

INT.

References

- Solbrekken, G., Chiu, C-P, Byers, B., and Reichenbacker, D., “The Development of a Tool to Predict Package Level Thermal Interface Material Performance,” Proceedings, ITherm Conference, May, 2000, pp. 48 – 54.

- ASTM Standard D5470-01, “Standard Test Methods for Thermal Transmission Properties of Thin Thermally Conductive Solid Electrical Insulation Materials.” Available for purchase at www.astm.org.