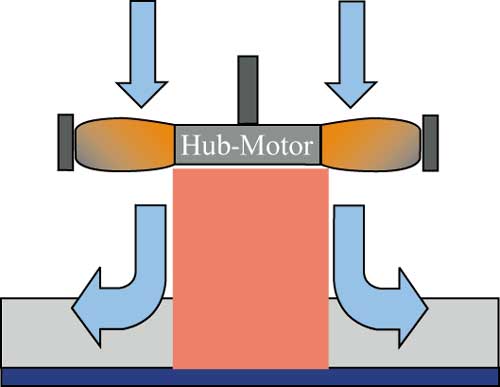

Conventional axial hub-motor AHS (Active Heatsink) devices (Figure 1) have reached their functional and cost limits and may not be improved significantly. These devices have a number of inherent, severe contradictions (design limitations) that determine the “evolutionary maturity” of this concept.

|

Figure 1. Conventional axial hub-motor AHS.

Let us look at different technologies and highlight their advantages and disadvantages.

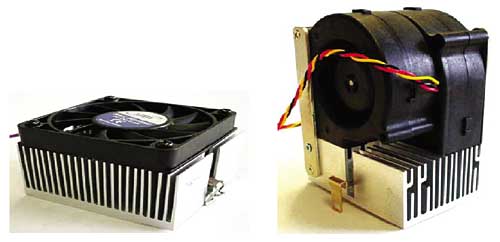

Big vs. Small Hub-Motor designs (Figure 2)

|

Figure 2. Illustration of the big vs. small hub-motor design concepts.

Big hub-motor designs generate enough power to achieve the required fan performance. However, they also substantially block the air flow to the hottest area: the heat sink.

Small hub-motor designs can partially block the air flow to the hottest area: the heat sink. However, they do not generate enough power to achieve the necessary fan performance.

Axial Fan vs. Centrifugal Blower designs (Figure 3):

|

Figure 3. Axial fan and centrifugal blower AHS.

Axial fan designs are flat and light. However, they only produce a low pressure.

Centrifugal blower designs produce a high pressure. However, they are bulky and heavy.

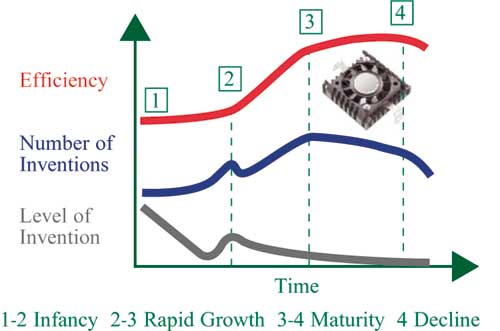

Analysis of the number and the level of inventions in the field of axial hub-motor AHS devices establishes the location of AHS concept on its S-curve of evolution (Figure 4). Figure 4 demonstrates the maturity of the technology as shown by “efficiency” (the red curve). Equally interesting is the number of patents in this area. The blue curve shows that the number of inventions has leveled off; a factor reflecting the maturity of the technology.

|

Figure 4. Location of the axial hub-motor AHS on S-curve of evolution.

In view of the steady increase in power dissipation and the demand for air cooling, a technology change is mandated. Clearly, the axial hub-motor AHS concept is very mature. Its parameters, including heat dissipation ratio, reliability, noise, size and cost, have reached their limits. Moreover, with the lack of technology development in this area, they can no longer be improved significantly.

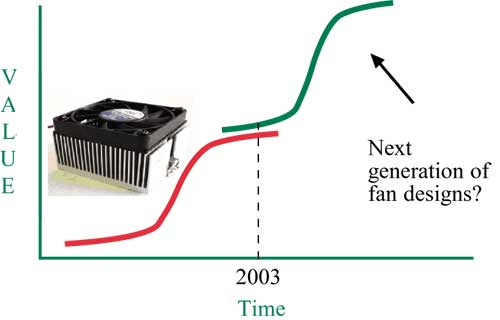

Thus, cooling the next generation of electronic devices will necessitate a new look, perhaps even a revolution, in the air delivery methods afforded through fan design. Attaining this goal will require the industry to migrate from today’s technology value curve (the red line in Figure 5) to the green curve, signifying the next generation of fan designs. It is therefore is incumbent upon the fan industry and the thermal design community to leverage the old technology and produce the next generation of air movers.

|

Figure 5. The technology and value curves depicting the break with today’s technology to create the next generation of air movers.