Introduction

Thermal management of electronic components must solve problems connected with the limitations on the maximum chip temperature and with the requirements on the level of temperature uniformity. To cool electronic components, one can use air and liquid coolers as well as coolers constructed on the principle of the phase change heat transfer in closed space; i.e., immersion, thermosyphon, and heat pipe coolers. Each of these methods has its merits and draw-backs because, in the choice of appropriate cooling, one must take into consideration not only the thermal parameters of the cooler but also design and stability of the system, durability, technology, price, application, etc.

Heat pipes are not in general a low cost solution to the cooling problem, but they are most effective and have great potential as power levels and volume requirements increase. For these reasons heat pipes have been applied up to now mainly in applications with special working conditions and requirements, such as in space thermal control, in aircraft devices, in traction drives [1,2], in audio amplifiers, in cooling of closed cabinets in harsh environmental conditions, etc.

Heat pipes, because of their high thermal conductivity, provide an essential isothermal environment with very small temperature gradients between the individual components. The high heat transfer characteristics, the ability to maintain constant evaporator temperatures under different heat flux levels, and the diversity and variability of evaporator and condenser sizes make the heat pipe an effective device for the thermal control of electronic components.

This review of applications includes recent advances and developments that affect the implementation of heat pipes in the thermal control of electronic devices. The applications fall into three categories:

- Heat Pipe Heat Sinks (HPHS), where the heat pipe is placed in contact with the component or device and serves the same function as a heat sink

- Mini/Micro Heat Pipes (MHP) and Heat Pipe Spreaders (HPS), where the device is an integral part of the heat pipe.

- Heat Pipe Heat Exchangers (HPHE), which are system level heat pipes, where the heat pipe is used to control temperature in equipment cabinets or systems.

This work focuses on recent applications of heat pipes in electronics industry. The paper describes the operating principles, modeling, design, and testing of heat pipes as applied to electronic applications and provides a comprehensive review of the specific applications.

Heat Pipe Operation

Heat pipes are sealed vacuum vessels that are partially filled with a working fluid, typically water in electronic cooling, which serves as the heat transfer medium. The heat pipe envelope is made of copper in a myriad of shapes including cylindrical, rectangular, or any other enclosed geometry. The wall of the envelope is lined with a wick structure, which provides surface area for the evaporation/condensation cycle and capillary capability. Since the heat pipe is evacuated and then charged with the working fluid prior to being sealed, the internal pressure is set by the vapor pressure of the working fluid.

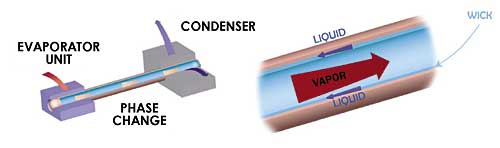

As heat is applied to the surface of the heat pipe, the working fluid is vaporized (Figure 1). The vapor at the evaporator section is at a slightly higher temperature and pressure than other areas. This creates a pressure gradient that forces the vapor to flow to the cooler regions of the heat pipe. As the vapor condenses on the heat pipe walls, the latent heat of vaporization is transferred to the condenser. The capillary wick then transports the condensate back to the evaporator section. This closed loop process continues as long as heat is applied.

|

Figure 1. As heat is applied to the surface of the heat pipe, the working fluid is vaporized.For a heat pipe to function properly, the net capillary pressure difference between evaporator (heat source) and condenser (heat sink) must be greater than the sum of all pressures losses occurring throughout the liquid and vapor flow paths. This relationship, referred to as the capillary limitation, can be expressed mathematically as follows [3,4] :

Pcmax is the maximum capillary pressure difference generated within the capillary wicking structure between the evaporator and condenser,

Pl and

Pv are the viscous pressure drops occurring in the liquid and vapor phases, respectively, and

Pg represents the hydrostatic pressure drop.When the maximum capillary pressure is equal to or greater than the sum of these pressure drops, the capillary structure can return an adequate amount of working fluid (priming or repriming of the heat pipe) to prevent the evaporator wicking structure from drying out. When the sum of all pressure drops exceeds the maximum capillary pumping pressure, the working fluid is not supplied rapidly enough to the evaporator to compensate for the liquid loss through vaporization, and the wicking structure becomes starved of liquid and dries out (depriming of the heat pipe). This condition, referred to as capillary limitation, varies according to the wicking structure, working fluid, evaporator heat flux, operating temperature, and body forces [5].

Heat Pipe Wick Structures

The main distinction of heat pipes, besides working fluid, is the wick structure. There are several types of wick structures: screen, grooves, felt, and sintered powder. Sintered powder metal wicks offer several advantages over other wick structures. One advantage of a heat pipe with a sintered powder wick is that it can work in any orientation, including against gravity (i.e., the heat source above the cooling source). The power transport capacity of the heat pipe will typically decrease as the angle of operation against gravity increases. Since groove and screen mesh wicks have very limited capillary force capability, they typically cannot overcome significant gravitational forces, and dry out generally occurs.

An emerging advantage of the sintered powder wick is its ability to handle high heat fluxes. Since sintered powder wicks are generally 50% porous, there is accordingly a large surface area available for evaporation. Typical sinter powder wicks handle 50 W/cm2, and have been tested to 250 W/cm2. In comparison, a groove wick will nominally handle 5 W/cm2 and a screen wick will nominally handle 10 W/cm2.

Additionally, since a sintered powder wick is integral with the heat pipe envelope, and the fluid charge is only enough to saturate the wick, the heat pipe can be subjected to freeze/thaw cycles with no degradation in performance. Moreover, the heat pipe including the sintered powder wick structure can be bent in different shapes. The above attributes make the sintered powder wick the optimal structure for many thermal management solutions.

Heat Pipe Electronic Cooling Applications

Heat Pipe Heat Sinks (HPHS)

The most versatile feature of using heat pipes is the wide variety of geometries that can be constructed to take advantage of the available space around the electronics to be cooled. For example, Figure 2 shows heat pipe systems that are in high volume production. In many applications, the available heat sink volume above the electronics is limited by the board-to-board spacing. In this situation, heat pipes are used in a low profile design that transports the heat to a large fin stack.

|

Figure 2. Examples of heat pipe systems that are in high volume production.In general, the smaller component cooling approaches transport 10 to 100 W each. Almost every current notebook computer uses a heat pipe in its thermal management design. Most of these heat pipe-heat sinks use a 3 or 4 mm diameter heat pipe that carries the power from the CPU to a large aluminum plate. The heat is then conducted into the EMI shield of the keyboard, through the keyboard, and into the ambient air by natural convection and radiation. This type of passive design has been a very effective thermal management technique for CPUs with power ratings less than 10 W.

Most recent designs incorporate a heat sink/fan/vent with the use of a heat pipe. This concept permits the notebook designer to locate the CPU independent of the heat sink. This allows the notebook designer to design the most effective heat exchanger and an optimal airflow path. The optimal design helps to reduce airflow requirements and noise. One of the limiting factors is the volumetric airflow that current DC fans can produce reliably. Because of size and voltage restrictions, fans must run at higher RPM. This, of course, has an effect on noise and the life of the fan. Most applications use an aluminum evaporator block (heat input section), the heat pipe (heat transport section), and aluminum fins (heat sink section).

In situations where there are several hundred watts to several kilowatts to be rejected, the electronics are mounted on large heat pipe units inside cabinets. Figure 3 shows different heat pipe units that can handle several IGBTs. The IGBTs are attached to a mounting plate and heat pipes, embedded in the plate, transport the heat to an air-cooled fin section. There are several different sized units like this being used in the field. Heat rejection from units like these is from 500 W to 10 kW.

|

Figure 3. Examples of heat pipe units that can handle several IGBTs.Different fin configurations can be considered (Figure 3). Standard fins are generally used for applications where heat dissipation and airflow rate are low. For applications where high heat dissipation is needed, corrugated fins are employed to enhance the air convection. These fins must be optimized when designing the whole system in order to account for the pressure losses.

Different heat pipe system designs can be considered depending on the electrical insulation level needed in the application. For those applications where high electrical insulation is considered, electrically insulated material is bound around the heat pipes so that high voltages up to 12 kV can be applied between the evaporator and condenser sections without electrical breakdown.

Heat pipe assisted heat sinks can manage non-uniform heating and high heat fluxes better than conventional heat sinks. Heat pipes can be installed in the base of an extrusion to reduce the conduction spreading resistance. Spreading resistance occurs when a heat source’s footprint area is smaller than that of the heat sink’s base.

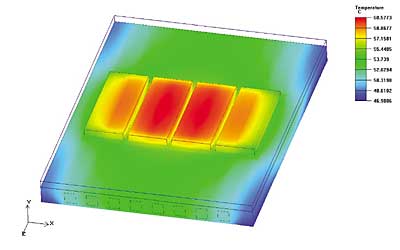

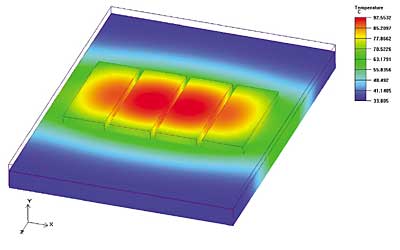

Figure 4a shows an extrusion (300 x 400 x 100 mm [LWH]) that was tested using forced convection (air speed around 4m/s and air inlet temperature around 20°C) with a heat source footprint of 140 x 240 mm and a power dissipation of 3000 W. Tests are performed with the heat source in the center of the extrusion. The extrusion shown has a base thickness of 18 mm, and eight 15 mm diameter heat pipes are installed in the base of the extrusion.

|

a)

|

b)

c)

Figure 4a. An extrusion that was tested using forced convection.

4b. Temperature profiles at the surface of the extrusion without heat pipes.

4c. Temperature profiles at the surface of the extrusion with heat pipes.The temperature profiles at the surface of the extrusion without and with heat pipes appear in Figures 4b and 4c, respectively. The shape of the temperature profiles in Figure 4c demonstrates that heat pipe heat sinks can handle centered power input while maintaining a relatively uniform heat sink temperature. With heat pipe assisted heat sinks, the thermal designer has the freedom to place the electrical components in convenient locations and is not limited by spreading resistance to the center of the heat sink.

As shown in Figure 4c, the heat pipes also significantly reduced the maximum surface temperature of the extrusion. By simply adding heat pipes to the base of an existing heat sink, the overall sink to ambient temperature rises are reduced by 30%. Faced with high spreading resistance, the thermal designer would probably explore the feasibility of increasing the base thickness in an effort to reduce both the heat transfer by conduction and by mass.

Flat Mini Heat Pipes (FMHP) and Heat Pipe Spreaders (HPS)

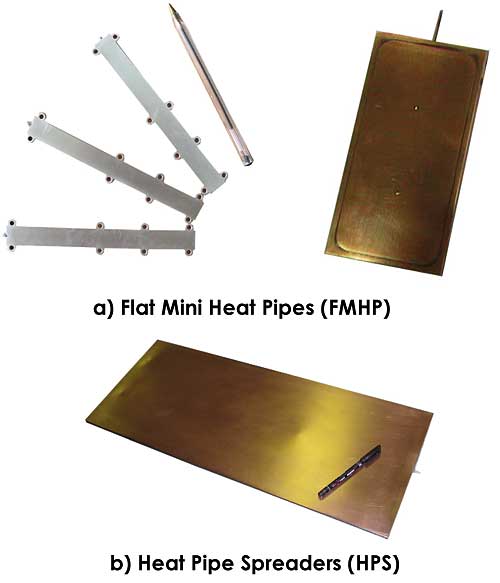

Flat Mini Heat Pipes (FMHP) and Heat Pipe Spreaders (HPS) are currently receiving a lot of attention (Figure 5). The vapor chamber provides a uniform temperature across the heat dissipation surface with low mass. This technology allows direct attachment of heat dissipation fins and can be used in air-cooling applications for microprocessors, RF frequency transmitters, thermoelectric devices, and power modules.

|

Figure 5. Examples of Flat Mini Heat Pipes (FMHP) and Heat Pipe Spreaders (HPS).

Heat Pipe Heat Exchangers (HPHE)

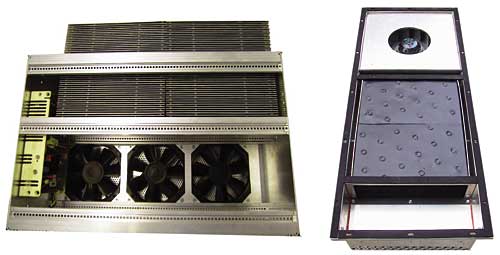

In many cabinet-cooling situations, there is always additional heat to be rejected from electronics that are not cooled with heat sinks directly. In those situations, it is best to use an air-to-air heat exchanger designed for cooling indoor/outdoor electronic cabinets. For example, Figure 6 shows a double-sided heat exchanger designed to achieve significantly improved heat transfer while reducing heat exchanger size. Heat load dissipation from 500 to 3000 W has been demonstrated.

|

Figure 6. A double-sided heat exchanger designed to achieve significantly improved heat transfer while reducing heat exchanger size.These HPHE are ideal for cooling electronics in applications where the circuitry must be enclosed and isolated from dust, moisture, oil mist, or harsh environmental conditions. Since the point at which the heat pipe passes through an enclosure can be sealed easily, it is possible to obtain a closed, airtight system that prevents external contamination. The HPHE can be also used for applications where heat is transferred by natural convection.

Conclusion

In summary, this article shows a progression of cooling approaches that thermal engineers can use to address the demands of the growing heat dissipation levels of power electronic devices. Small heat pipe assemblies (low heat dissipation from 10 to 100W) allow increased heat sink performance within the volume available with little potential impact on the existing system design.

The use of heat pipes for the thermal management of notebook computers is a proven and widely applied technology. The heat pipe has helped to propel the notebook industry to its current level. Heat pipe designs are easily handling current requirements and allow additional notebook design flexibility. The next generation of notebooks is limited by the amount of power that can be handled by their thermal management systems.

Heat pipes are now being combined with other technologies to help meet these emerging requirements. In situations where the heat to be rejected is several kilowatts, large heat pipe assemblies can be used. Ultimately, these large cooling units might be the best solutions for keeping pace with the increasing heat loads of power semiconductors. After cooling the electronics, which generate the most heat, there is always heat from other electronics in the cabinet. A sealed air-to-air heat exchanger is best for dealing with the residual heat inside the cabinet.

The reliability and flexibility of the heat pipe has proven to be a valuable attribute that provides the system designer with increased layout possibilities and typically improves thermal performance. The fin stack height, width, length, and fin spacing can be customized to fit the application. With the reductions in heat pipe prices as volume production increases, more industries are now accepting heat pipes as thermal management tools.

Heat pipes offer an attractive approach to supplementing conventional heat sink solutions. They provide a tool that allows the designer to reconfigure and/or extend the performance of more conventional heat sinks such as extrusions or castings. When performance dictates, they allow the thermal designer to utilize a recently accepted heat sink alternative, the heat pipe heat sink assembly. The heat pipe heat sink assembly permits the designer to achieve otherwise unreachable thermal resistance levels via the efficient maximization of the heat sink surface area available for dissipation to the ambient air.

Historically, the application of this technology has implied significant costs; however, with the widespread application of the technology, costs are falling rapidly. Typical heat pipe heat sink assemblies are used in the portable computer market, where the highest production volumes currently exist. Higher performance units for workstation/server applications are several times that cost (for several times the performance).

The application of heat pipe heat sinks can in almost every instance yield improved heat sink efficiency and performance. This improvement, either in terms of permitting higher packaging densities or permitting higher power dissipation in a given volume, must be evaluated against the increased cost for such an assembly.

In portable computers the application of heat pipes has become the accepted standard since the only way to achieve the required performance in the available volume is through the use of heat pipes. In high power servers and super computers the use of heat pipe heat sink assemblies has been shown to offer both cost and performance advantages. With the spreading acceptance, production volumes are increasing and costs are falling. This trend is, in turn, resulting in an expanding market with broader application boundaries.

References

- Tantolin, C., Godet, C., Zaghdoudi, M.C., “Heat Pipe Thermal Behavior from Frozen Start-up”, PCIM 2000, N�remberg, June 5-9, 2000, pp. 355-360.

- Tantolin, C., “Cooling Of High Dissipated Electronic Components By Immersion Within Dielectric Fluid : Study of Heat Transfer Exchanges by Boiling/Condensation/Convection”, Ph. D. Thesis (in French). INSA de Lyon, France, 1994, p. 287.

- Faghri, A., Heat Pipe Science and Technology, Taylor & Francis, Washington, D.C., 1995, p. 874.

- Peterson, G.P., An Introduction to Heat Pipes : Modeling, Testing and Applications, John Wiley & Sons, 1994, p. 356.

- Garner, S.D., “Heat Pipes for Electronics Cooling Applications”, ElectronicsCooling, Vol. 2, No. 3, 1996.