Small Fans for Cooling Small Electronic Devices

Masaharu Miyahara, Sunonwealth Electronic Machine Industry Co., Ltd.

The growing portable device market boosts the development of small electric devices, such as Ultra Mobile PC, Pico projector, Smart Phone, etc. One laptop cooling solution is the fan-less cooling technology that

transports the CPU heat by using a heat pipe. However, this solution has a limitation in transferring laptop heat to its ambient environment, due to the small laptop area and its limited surface temperature.

Additionally, when the total heat dissipation in a laptop is over 20 W, fan-less cooling is not ideal for system cooling even if it can successfully transfer heat from the CPU, because then other components such as

the HDD and DVD drives would be negatively influenced by the CPU heat. Moreover, the high temperature of the laptop surface could result in human skin burns.

It is interesting to examine the laptop evolution from 1995 to 1998 when the dissipation increased by more than two since Intel released its “Pentium” CPU in 1995, causing the laptop to be the first electronic system

calling for a special small fan. The first laptop that used fan cooling was the Toshiba “SS590” (1995) with a Pentium 90MHz CPU and a Thermal Design Power of 6W. The fan used was an axial type of 25mm x 25mm x 10mm.

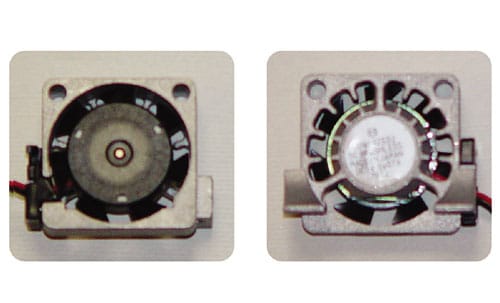

Its main feature was that the fan and the heat sink were structurally merged (See Figure 1). The CPU heat is transferred to the fan body (working as a heat sink) by an aluminum connector. This merge is crucial for

space saving. The fan body is the only airflow path and hence enables 100% airflow to the heat sink.

|

Figure 1. Heat sink integrated with fan.

The objective of any fan design should be to utilize the minimum amount of airflow that will allow the components to remain below their temperature limits, while also minimizing the sound level and power

requirement of the fan and taking care of the maximum allowable exit air temperature. The fan selected for a given application will determine both the airflow and thereby the temperature rise of the

air stream and the heat transfer coefficient on any heat transfer surface.

The drawbacks of fan cooling are: 1) acoustic noise level increase; 2) electric power consumption requirement; 3) fan reliability and failure. The question is how to cope with these problems. The best

solution to avoid acoustic noise is to choose a lower-noise fan for the same airflow and minimize the system’s airflow resistance. The recommended fan speed control solution is to use a low-speed start

-up followed by a gradual increase of the speed to its nominal operation. A PWM (Pulse Width Modulation) fan speed control, firstly used in the IBM “Think Pad”, is the most popular. It minimizes

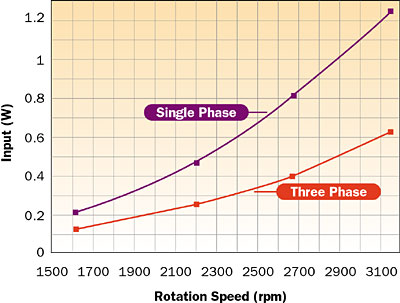

noise by controlling the fan speed at a level that is usually sufficiently effective for cooling. Electric power reduction could be realized through improved fan blade efficiency and motor efficiency. Three

-phase motor drive technology was adopted for laptops in 2007. Previously, this drive circuit required a large space. However, technological breakthroughs have allowed downsizing of the packaging as well

as a reduction in power consumption by almost a factor of two (see Figure 2). The main reason for fatal fan failure results from a poor bearing system. It should be designed for long life and high

temperature environment (often over 50�C). The latest “SLMS” (Super Long life Maglev System, the key technology is sleeve and oil) has reached an MTBF of 50k hours at 60�C.

|

Figure 2. Single-phase vs three-phase comparison.

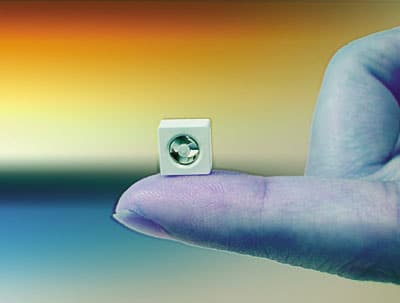

Most small-size laptop cooling fans range from 50mm x 50mm to 80mm x 80mm with thicknesses of 5mm to 11mm, but they are still not small enough for the latest small laptops, hence the demand for

even smaller and thinner fans. The smallest size and thinnest fans today measure 8mm x 8mm x 3mm (axial fan) and 9mm x 9mm x 3mm (blower), see Figure 3 for an example. Of course, next to application

-driven pressure drop and flow rate requirements, these small fans must also obey the required reliability considerations, especially at high operating temperatures.

|

Figure 3. Example of small fan size.

In summary, it may be noted that fan cooling technology continues to keep pace with increasingly smaller devices. The challenges to address are thinner, smaller size, and power saving, while keeping

the required high quality and reliability specifications.