Raghav Mahalingam

Nuventix Inc.

The cooling needs of data centers and server farms have increased rapidly over the last few years due to the advent of cloud computing. The use of large banks of fans is quite common in such systems and cooling system power is a significant fraction of the operational costs. Additionally, NEBS acoustic requirements limits the use of higher speed fans. As computing needs continue to grow, it is getting harder for system architects to stay with air cooling, though it is commonly preferred due to its simplicity. A methodology to extend the use of air cooling has been developed where localized synthetic jets are used in conjunction with system fans to improve the overall system performance, i.e., lower acoustics, lower power consumption and higher reliability.

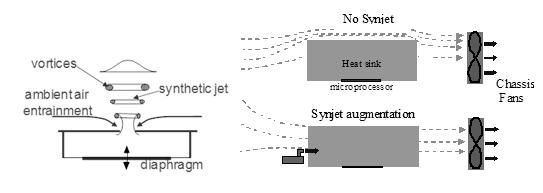

Synthetic jets are formed by periodic suction and ejection of fluid out of an orifice bounding a cavity by the time periodic motion of a diaphragm that is built into one of the walls of the cavity (Figure 1). Synthetic jets have been shown to alter the behavior of mean flows in aerodynamic flow control applications [1]. A similar principle can be applied in thermal management as shown in Figure 1, which shows the use of synthetic jets for controlling a fan induced flow passing over a heat sink. The dotted lines in the figure show the streamlines observed using smoke visualization. In the top figure, an un-ducted heat sink is subject to a fan flow that is pulling air through the heat sink where a significant portion of the incoming flow tends to flow over the heat sink. Adding synthetic jets upstream of the inlet to the heat sink enables re-entrainment of the inlet flow to reduce flow bypass while simultaneously breaking up the local boundary layers on the walls of the heat sink. This enables better performance at lower fan speeds. Lowering the fan speeds, or the fan RPM, has the benefit of lowering fan power, fan acoustics and increasing fan reliability. There are established relationships between fan RPM and power, acoustics and reliability [2]. Fan power increases as the cube of RPM, while noise increases linearly and failure rate linearly.

Figure 1. Schematic of fan augmentation with synthetic jets (not to scale)

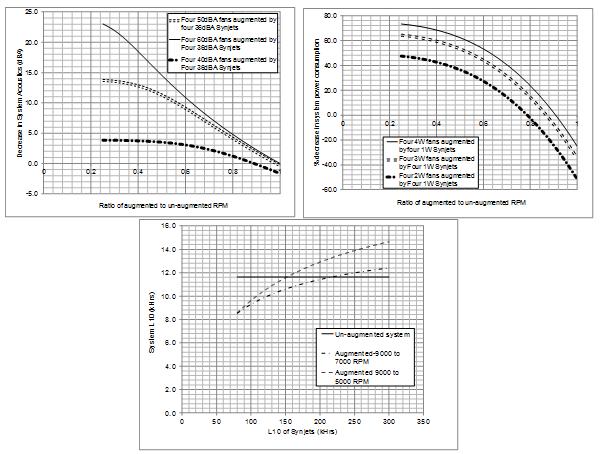

Figure 2 shows the theoretical effect of adding localized cooling on system acoustics, power and reliability. The amount of reduction that can be achieved in fan RPM is represented as the ratio of augmented to un-augmented RPM on the x-axis and is a critical parameter to achieve acoustic mitigation and power reduction with localized cooling. The improvement in overall reliability of the system including synthetic jets is the key to incorporating localized cooling. Traditionally, it has been assumed that localized active cooling is impractical since the addition of any extra moving parts in the system will decrease system life. However, this is only true if the life of the added cooling solution is comparable to the life of existing fans. As can be seen from Figure 2, the lifetime of the system depends strongly on the lifetime of the added localized cooling system. For example, even if the fan RPM can be reduced from 9000 to 5000, the localized cooling solution has to have an L10 of at least 150kHrs (The point of time at which at least 90% of units function as intended under stated conditions). Fans typically do not have such large L10 lifetimes. However, synthetic jets have been shown to have L10 lifetimes in excess of 300kHrs[3] and thus make localized augmentation feasible and actually, even beneficial from the standpoint of reliability.

Figure 2. Effect of addition of localized Synthetic jets to system acoustics, power and reliability

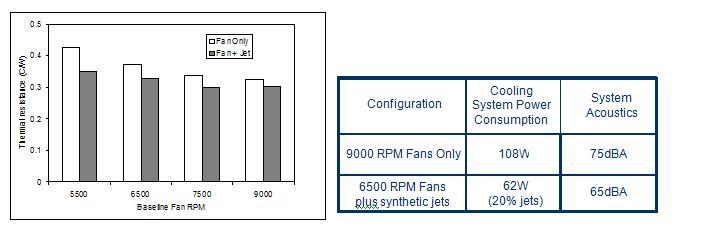

The increased performance of the augmented system is what drives the improvements in system acoustics, power and reliability. The case study below shows the efficacy of synthetic jet augmentation in a Newisys 4300 quad-socket, 3U, AMD Opteron rack-mounted model server. Figure 3 shows the case-to-ambient thermal resistance of one of the CPU’s with and without the jet augmentation at different fan speeds. At the idling speed of 5500 RPM the thermal resistance drops from about 0.43 °C/W to about 0.35 °C/W, while at the full speed of 9000 RPM, the performance goes from 0.33 to 0.3 °C/W. The system improvements in acoustics and power consumption at an equivalent thermal performance are significant as shown in the table on the right. A 33% reduction in cooling system power and a 10dBA reduction in system acoustics was achieved in this case study.

Figure 3. Decrease in thermal resistance due to the synthetic jet augmentation and improvements in system sound pressure level and cooling power consumption for equivalent thermal performance.

In summary, because synthetic jets have been demonstrated to have long life, they can be used to cool hot spots without reducing system reliability. This localized cooling in turn can be effectively used to reduce fan speeds, thereby improving system power consumption and acoustics.

References

- Glezer, A., and Amitay, M., “Synthetic Jets”, Ann. Rev. Fluid Mech., 34, pp. 503, 2002.

- http://www.comairrotron.com/airflow_note.shtml

- Schwickert, M., “SynJet Thermal Management Technology Increases LED Lighting System Reliability”, IEEE Reliability Society Annual Activities Report, http://www.ieee.org/reliabilitysociety, 2010.

- Mahalingam, R., Rumigny, N., and Glezer, A., “Thermal Management using Synjet Ejectors”, IEEE-CPMT, 27, 3, Sept. 2004.

- Mahalingam, R., and Glezer, A., “ Design and Thermal Characteristics of a Synjet Ejector Heat Sink”, Journal of Electronic Packaging, v127, n1, June 2005.