A new method of cooling extremely hot surfaces more effectively from researchers at MIT could benefit industrial equipment and electronic devices.

Considered by many to be a quieter, more efficient way of removing heat compared to traditional air cooling methods, liquid cooling is commonly used in a number of applications such as internal combustion engines in vehicles and portable machinery, industrial facilities, heat exchangers, high-end personal computers and other electronic systems.

However, there is a limit to what liquid cooling can accomplish, say researchers in MIT’s Department of Mechanical Engineering, citing the example of emergency crews’ inability to adequately cool Japan’s Fukushima nuclear power plant using seawater after an earthquake and tsunami struck the country in 2011. According to Kripa Varanasi, the Doherty Associate Professor of Ocean Utilization in MIT’s Department of Mechanical Engineering and the lead author of the study, one possible explanation for the limit is that when water droplets hit extremely hot surfaces, instead of boiling they instantly begin to evaporate, forming a thin layer of vapor and then bouncing along it, as they would in a hot cooking pan.

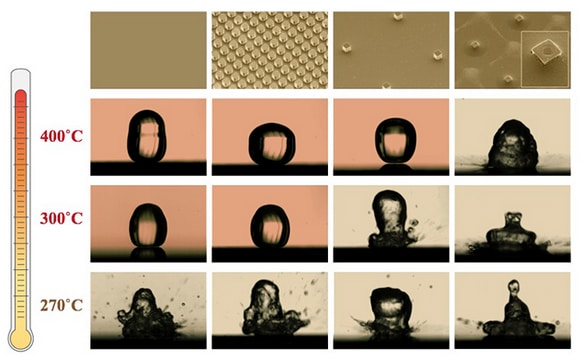

To solve this problem, Varanasi and his co-authors, recent MIT Ph.D. recipient Hyuk-Min Kwon and former MIT postdoc J.C. Bird, developed a way to keep the water droplets from bouncing as part of a method to cool hot surfaces more effectively. The method involves adding tiny microscale silicon posts to a smooth silicon surface to create a textured surface. The team found that the new textured surface could be heated at least 100°C higher than the smooth surface before the water droplets transitioned from landing to bouncing; however, it worked best when the posts were relatively spread out.

“That result was surprising,” Bird, who is now an assistant professor of mechanical engineering at Boston University, said. “Common knowledge suggests that the closely spaced posts would provide greater surface area [and] so would hold onto the droplets to a higher temperature.”

The research has major implications for a variety of systems, says Varanasi, including steam generators, industrial boilers, fire suppression and fuel-injected engines, as well as for electronics cooling.

“Our new understanding of the physics involved can help people design textured surfaces for enhanced cooling in many types of systems, improving both safety and performance,” he said. The results of the study are published in the journal Applied Physics Letters.

Yoav Peles, a professor of mechanical, aerospace, and nuclear engineering at Rensselaer Polytechnic Institute in New York who was not involved in this research, believes the new development could mark a potential turning point in the thermal management industry.

“Extending the surface temperature at which [this phenomenon] occurs is a challenging task that has been a century-long research effort,” he said. “The groundbreaking ‘hierarchical’ texture developed by Varanasi’s research group is a very promising approach to overcoming the unresolved obstacles faced by previous generations of thermal engineers.”