Researchers from the U.S. Department of Energy have developed a new technique that combines carbon nanotubes and organic materials to enable more efficient cooling of microprocessor chips.

While carbon nanotubes have long been known to offer high thermal conductivity, widespread application in cooling systems has proven difficult because of their high thermal interface resistance.

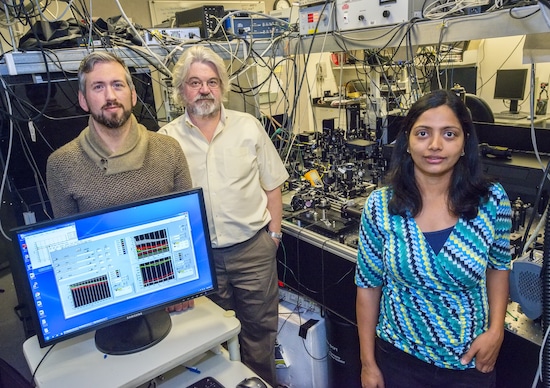

“The thermal conductivity of carbon nanotubes exceeds that of diamond or any other natural material but because carbon nanotubes are so chemically stable, their chemical interactions with most other materials are relatively weak, which makes for high thermal interface resistance,” Frank Ogletree, a physicist with Berkeley Laboratory’s Materials Sciences Division and leader of the study, said.

Now, Ogletree and his colleagues claim to have solved this issue using organic compounds to form strong covalent bonds between carbon nanotubes and the metal surface of the chip. The resulting thermal interface material conducts heat six times more effectively and is compatible with aluminum, silicon, gold and copper.

“We’ve developed covalent bond pathways that work for oxide-forming metals such as aluminum and silicone and for more noble metals such as gold and copper,” Ogletree said. “In both cases, the mechanical adhesion improved so that surface bonds were strong enough to pull a carbon nanotube array off of its growth substrate and significantly improve the transport of heat across the interface.”

In addition, the new bonding technique adds just seven microns on each side of the CNT layer during the bonding process, compared to older methods of bonding carbon nanotubes to cooling surfaces that add 40 microns.

“You can think of interface resistance in steady-state heat flow as being an extra amount of distance the heat has to flow through the material,” Sumanjeet Kaur, lead author of the research paper and an expert on carbon nanotubes, explained. “With carbon nanotubes, thermal interface resistance adds something like 40 microns of distance on each side of the actual carbon nanotube layer. With our technique, we’re able to decrease the interface resistance so that the extra distance is around seven microns at each interface.”

The team is now working on a method to improve the density of carbon nanotube/metal contacts in order to ensure all individual carbon nanotubes within an array make contact with the metal surfaces. The technique should also be applicable to single and multi-layer graphene devices, which face similar cooling issues.

“Part of our mission at the Molecular Foundry is to help develop solutions for technology problems posed to us by industrial users that also raise fundamental science questions,” Ogletree says. “In developing this technique to address a real-world technology problem, we also created tools that yield new information on fundamental chemistry.”

The research is published in the journal Nature Communications.