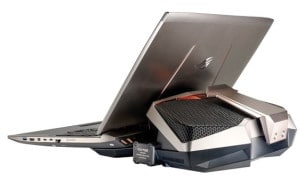

The World’s First Liquid-Cooled Gaming Laptop

The Asus ROG GX700 has been introduced as the world’s first liquid-cooled gaming laptop.

Asus ROG Global Marketing Director Derek Yu created the inch-thick laptop with a Nvidia GTX 980M graphics card, and with the cooling system as a “massive, alien-like pod filled with the extra hardware” that plugs right into the laptop, according to TechRadar.com.

The liquid cooling system is split in half to solve the space problem of needing room for pumps and radiators, and the GX700 only has a few extra components including “water-channels and water for the coolant to pass through,” while the aforementioned components are found inside the liquid cooling dock, TechRadar.com reports.

Yu explains, “The water cooling section interacts with the existing heat pipes thermal system inside the laptop, so those two work in tandem together. […] But now the water cooling part will take away, [and] offload the heat away from the system toward the radiators [on the dock].”

The laptop has also been equipped with a water-tight seal to prevent spills or leaks.

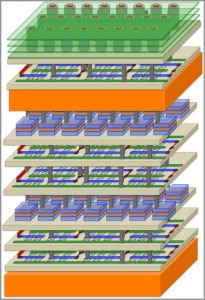

New High-Rise Nano-Materials Incorporate Thermal Cooling Layers

Researchers and Stanford engineers are creating a new approach to the layout of computer processors and memory chips (called Nano-Engineered Computing Systems Technology, or N3XT) where processors and memory are stacked on top of one another like a high-rise architecture.

This could cause immediate problems involving heat, but Stanford mechanical engineers Kenneth Goodson and Mehdi Asheghi have a solution.

“Just as skyscrapers have ventilation systems, N3XT high-rise chip designs incorporate thermal cooling layers,” reports Phys.org, “This work, […] ensures that the heat rising from the stacked layers of electronics does not degrade overall system performance.”

A working prototype has been demonstrated as “a thousand times more efficient in carrying out many important and highly demanding industrial software applications,” according to Phys.org.

New Design for Fighter’s Thermal Management Tech

Northrop Aerospace Systems has released a new artistic concept of a sixth-generation fighter that will combine new technology present in the Lockheed Martin F-22 and B-2 with new thermal management technology.

According to FlightGlobal.com, Northrop president Tom Vice is putting new focus on the quality of managing the heat generated by future weapons and sensors as it has been overlooked in the past.

“Northrop’s sixth-generation fighter concept shows the stealthy, swept-wing fighter using a powerful laser weapon to engage multiple targets. Even the best high-power lasers are only 32-33% efficient, meaning 2MW of heat is generated for every 1MW of energy that can be formed into a laser beam,” said Vice to FlightGlobal.com.

Vice adds that “Northrop is pursuing a concept instead that does not rely on accumulators or offboard venting to manage the heat.” Such options invite problems like raising the aircraft’s visibility and weapon limitations.

Although Northrop is not revealing exactly what their thermal management plan is, FlightGlobal.com reports that “Northrop’s concept shows a tailless, possibly supersonic vehicle, promising a new breakthrough in manoeuvrability, speed and stealth for a combat aircraft,” as well as a swept wing.

LEDs Can Be Infrared Trackers

Enlighted Inc. is offering LED lighting services that track people and objects by detecting infrared heat.

According to EENews.com, Enlightened Inc. is installing LEDs along with a tiny disk and antennae packed with a “light sensor, a temperature gauge, a power meter and a motion sensor, as well as wireless devices that communicate with the building-management system, with the other lights and with local smartphones.”

“The tracking systems work by means of the sensor modules, installed every 100 square feet with each overhead light,” explains Zach Gentry, the vice president of marketing at Enlighted.

Each sensor detects infrared heat and samples 60 times a second to distinguish between a still person and a heater, for example, according to EENews.com, “meanwhile, the light sensors watch for subtle changes in illumination as light reflects off a passing secretary. Computer servers, hosted in the cloud, stitch the data streams into an image.”

Then the system can mesh its data with other systems in the building as well as daylight and weather to “manage light levels,” or “pair room occupancy with HVAC data, so the building knows which rooms to heat and cool when,” reports EENEws.com.

Enlightened is also considering sticking “coin-sized beacons” on equipment such as company laptops to track where they are in case they get stolen, says EENews.com.

Gentry claims that LEDs not only use less energy than overhead fluorescent tubes”, but this upgrade can also “drop the electric bill by 90 percent.”

Half of North America Upgrading Data Center Cooling Systems

New research done by Emerson Network Power recently shows that nearly 50 percent of the United States and Canada have made thermal upgrades to their data center cooling systems.

According to the survey of “IT, facilities, and data center managers, […] while 40 percent of data centers have been upgraded in the past five years, nearly 20 percent are in process and about 31 percent will be upgraded in the next 12 months,” reported ACHRNews.com.

ACHRNews.com stated that the “need for higher equipment reliability, greater energy efficiency, and additional capacity” drove these upgrades.

“62 percent of the upgrades are in data centers under 10,000 square feet and 18 percent are in data centers larger than 50,000 square feet” as found in the survey according toACHRNews.com.

John Peter Valiulis, vice president of thermal management marketing for Emerson Network Power in North America, explained, “As the edge and cloud computing become ubiquitous, ensuring the health of cooling systems at smaller, localized data centers and computer rooms is crucial. Thermal upgrades are allowing companies to improve protection, efficiency, and visibility within all these spaces.”

Another finding from the survey was that “40 percent were adding economizers to provide “free cooling” when outside temperatures allow,” according to ACHRNews.com.

New “Kinetic Cooling Engine” CPU Cooler Design

Startup MIT company, CoolChip, demonstrated a new commercial prototype CPU cooler recently at CES.

“They’ve partnered with Cooler Master to release a “kinectic cooling engine” that can cool a chip 50 percent more efficiently than a conventional cooler, in a form factor that’s half the size and emits much less noise,” according to Spectrum IEEE.

It is true that “Sandia Labs was working on an idea for an entirely new type of CPU cooler called an “air bearing heat exchanger,” that is very similar to CoolChip’s new “kinetic cooling engine”, but “…CoolChip has invested heavily in technology development beyond the original Sandia Labs concept with high-volume manufacturability, high-volume production pricing, and reliability considerations taken into account,” reported Spectrum IEEE.

In addition, Sandia doesn’t make commercial products, so CoolChip is taking all the benefits from the design, “more robust cooling, higher efficiency, lower noise, and dust resistance,” and putting them on the market, according to Spectrum IEEE.

CoolChip’s Kinetic Cooling Engine “should arrive later this year through Cooler Master [and] should be competitive in cost with other CPU cooling systems,” according to Spectrum IEEE.

Redesigned Heat Sinks Using 3D Printers

Plunkett Associates has successfully redesigned heat-sinks to improve convection cooling performance using Direct Metal Laser Sintering (DMLS), or 3D printing.

“Each heat-sink was first produced in virtual form and simulated using Computational Fluid Dynamics (CFD) software,” reported 3Ders.org.

“The top five heat-sinks were then built by 3T RPD Ltd. using DMLS and physically tested to confirm the accuracy of the virtual tests,” according to 3Ders.org.

3Ders.org reports that Plunkett Associates turned to the DMLS process because the “revamped 3D printed components possessed [such] complex internal architectures” they “could not be replicated using other manufacturing processes.”

“All five models showed a significant improvement over a standard extruded heat-sink,” confirmed 3Ders.org.