by MP Divakar, PhD, Stack Design Automation

Technical Editor, Electronics Cooling Online

Earlier in August of this year, Electronics Cooling featured an article on energy efficiency of data centers where a review of the energy consumed by the IT and non-IT equipment and its optimization by deterministic (DCIM) and AI methods (Google’s Deepmind) was presented. The ‘occupants’ of a data center, barring a few network techs and engineers, are all machines whose Silicon ‘hearts’ can withstand temperatures much higher than those of humans! As such, the cold and hot aisle temperatures in data centers have inched upward to achieve better power usage effectiveness. For the personnel servicing IT equipment, one of the workarounds of higher aisle temperatures has been to switch the airflow in cold aisle inlets as needed to insure personal comfort and then revert to a regular status when service is complete.

In this article, we will explore the research trends underway in various research institutions and the industry to achieve further savings in energy by optimizing how human beings consume energy. While it is true that human beings lose a majority of the body heat from their head and chest areas, there are opportunities to optimize how human bodies respond to hot ambient conditions using smart clothing, a literal category of wearable electronics. Perhaps when Walt Whitman wrote one of his famous poems “I Sing the Body Electric,” one of the twelve poems in the first edition of Leaves of Grass (1856/67), he had no clue that bidirectional thermoregulation of personal clothing on a human body would be enabled by the ‘electric!’

Since the early space age generation of personal heat and cooling, there has been a rapid progress in materials for making artificial fabric that enable better thermal regulation of human bodies while keeping or even improving the personal comfort levels. The end goal is to increase the set point for indoor energy regulation in office buildings, shopping malls, multi-tenant dwellings and homes.

If personal thermal management is addressed by facilitating heating or cooling only to a human body and its local environment, then the energy needed for heating and cooling an entire building can be significantly reduced. In comparison to buildings including homes, the human body has much smaller thermal mass and this difference is much larger in office buildings. The potential payoff from such savings will have a huge impact on energy costs, not to mention the impact on environment and climate change. This US Department of Energy (DoE) note explains that moving the thermostat temperature a few degrees higher or lower (in cooling / heating, respectively) for 8 hours a day can result in 10% energy savings.

Materials like nanoporous polyethylene (nanoPE) are transparent to mid-infrared (IR) human body radiation but opaque to visible light because of the pore size distribution (50 to 1000 nanometers). This illustrious Science magazine article by Stanford University researchers (and sponsored by ARPA-E, see below) highlights more on the thermal characteristics of nanoPE materials. While such smart eTextiles have great benefits, the IR-transparent textile must also be wearable and allow water-wicking and air permeability, i.e., they must breathe! Nevertheless, such materials are the enablers of personal thermal management systems and thus represent a platform on which wearable cooling solutions can be developed.

ARPA-E Programs

The DELTA program (Delivering Efficient Local Thermal Amenities) has multiple R&D activities currently underway to address energy savings by personal thermoregulation. Starting with this edition, Electronics Cooling will publish a series of articles on this topic by inviting the participants of ARPA-E DELTA program. In this blog, more information on the work done at University of Maryland (UMD), a participant of the ARPA-E program is provided.

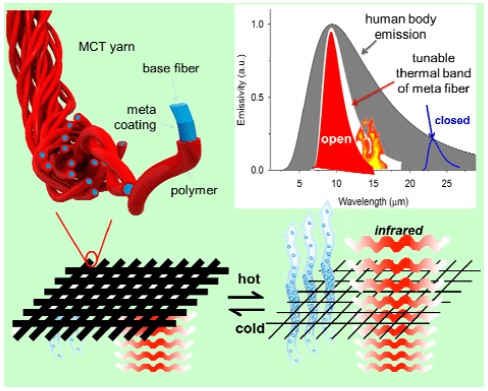

UMD’s work on Meta-Cooling Textile (MCT) involves developing a thermally responsive clothing fabric to maintain personal comfort in hotter or cooler indoor settings. However, this program attempts to go a step beyond material innovation by providing clothing with active control over the primary channels for energy exchange between the body and the environment. This is done by increasing or decreasing the diameters of the nanopores as needed for regulating body temperature.

The technology being developed at UMD is shown pictorially in the figure below. Active IR emissivity control is achieved using a metamaterial coating and synergetic air convection. UMD researchers aim to achieve this in a self-powered mode whereas the state-of-the art (e.g. Nike Sphere React) smart clothing requires 2.5 to 5.0W of power and is bulky. Cost and weight of the fabric are other targets that favor the UMD researchers, should the research succeed –they only hope to add 2.5% increase in weight and a cost increase of $0.88 to $3.42.

Electronics Cooling is actively working with all researchers of ARPA-E’s DELTA program for guest articles. Stay tuned as we will bring you more information on electronics cooling of people!