Supercapacitors (also referred to as electric double-layer capacitors (EDLC), electrochemical capacitors, electrochemical supercapacitors, and ultracapacitors) are a class of energy storage devices that bridge the gap between electrolytic capacitors and rechargeable batteries. Supercapacitors can typically store 10 to 100 times more energy per unit volume or mass than their electrolytic equivalents. They can also charge/discharge much faster than batteries and can withstand many more charge/discharge cycles. Their capacitance ranges from three to six orders of magnitude larger than those of electrolytic capacitors, but their voltage limits are lower. They are termed “super” because of the high surface area of their electrodes and the very small separation distance between the positive and negative charge.

Supercapacitors essentially consist of two electrically conducting plates or electrodes separated by a dielectric different from the conventional solid dielectrics. Unlike electrolytic capacitors, the charge in supercapacitors is stored at the interface between an electrode and an electrolyte, with each electrode-electrolyte interface representing a capacitor. A two-terminal supercapacitor device is therefore equivalent to two conventional capacitors in series. Supercapacitors are used today in many power-management applications that demand fast charge/discharge cycles. Examples of their applications include hybrid electric vehicles (HEV), energy harvesting, regenerative braking, microgrids, consumer electronics, etc. This diverse set of supercapacitor applications with varying power demands will often result in unwanted thermal effects that need to be effectively dealt with.

In this blog, Electronics Cooling is pleased to present a review of the book Thermal Effects in Supercapacitors by Xiong, Kundu and Fisher, and published by Springer in 2015. Thermal management is one of the important issues that affect supercapacitor performance (like Li-ion batteries). Knowledge of the thermal stability of different components of the supercapacitor (packaging, electrodes, electrolytes, and separators) is necessary in the design of supercapacitors that operate over wide temperature ranges and charge/discharge rates. A monograph like this is expected to provide a broad coverage on the current state of knowledge of such topics for practicing engineers.

Organized into 6 chapters, the book begins with an introduction to the Thermal Management in Electrochemical Energy Storage Systems. After discussing the types of electrochemical energy storage devices such as batteries, capacitors, fuel cells and combinations thereof, the prime performance metrics for comparing these technologies are presented. These metrics are reliability, power and energy density, cycle-life, temperature range and emission of pollutants. Batteries and capacitors are closed systems with anodes, cathodes and separators that are soaked with electrolytes and sealed in a single compartment. The chapter also introduces the concept of the Rugone (pronounced “ru-GO-nee”) chart which provides a performance comparison of various energy-storing devices.

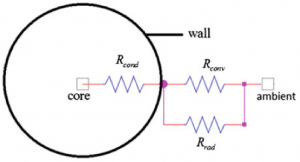

The primary mechanism of heat generation in supercapacitors is Joule heating. The heat flow paths are by conduction within the cell and by convection and radiation from the capacitor wall to the ambient. The ambient temperatures, where the supercapacitors are deployed, have a major influence particularly at the extremes. Most supercapacitor manufacturers specify the safe operating temperatures in the range of −40 to 70°C.

Chapter 2 presents more treatment of the subject matter on Thermal Considerations for Supercapacitors. They have excellent low temperature performance which can meet the power needs in extreme weather conditions in heavy electrical applications. In HEVs and EVs, supercapacitors are used for capturing and storing energy from regenerative braking and supplying vehicle acceleration or boost power supplementing the Li-ion batteries or fuel cells. With the popularity of smaller form factor micro-supercapacitors, thermal performance in portable and consumer electronic devices needs to meet extreme temperature conditions. Similar to their macro counterparts, the thermal behavior of the micro supercapacitors depends primarily on the electrolyte which must be thermally robust under a wide range of operational temperatures. Chapter 2 describes detailed methods to characterize the thermophysical properties of supercapacitor components.

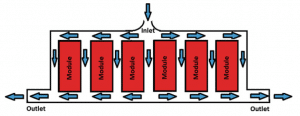

Commercial supercapacitor packs typically include multiple interconnected individual cells which must be cooled to minimize temperature gradients across cells, while at the same time the cells are expected to meet working environments such as shock, vibration, ambient temperatures and corrosion from water, dust, and debris.

Passive cooling systems for supercapacitors also employ phase change material (PCM) which dissipates the heat generated within the cells of a module by conduction. Ideal candidates for PCM cooling should have a melting point between 30 and 60 °C, high latent heat per unit mass, and a narrow melting temperature range. Paraffin wax is most common because of its low cost and chemical stability.

Chapter 3 provides more description of the Influence of Temperature on Supercapacitor Components –electrolytes such as Aqueous Electrolytes, Organic Electrolytes, Ionic Liquids (IL) and Polymer Gel Electrolytes. The effects of temperature on thermophysical properties of other components including electrodes (active electrode materials, current collectors, and binders) and separators are also discussed. Common metrics to all types of electrolytes include a wide voltage window, high ionic conductivity and thermal stability over a wide temperature range, low cost, low viscosity, low volatility and low toxicity.

Chapter 3 succeeds in conveying the importance of electrodes’ thermal conductivity as well as electrical conductivity. For example, high electrode porosity might not be beneficial for heat conduction although it favors charge storage at the electrode’s surface.

The importance of temperature effects on separators is also emphasized. Separators prevent direct electrical contact between positive and negative electrodes while permitting rapid transport of the ionic charge carriers. The overall ESR (equivalent series resistance) of the cell is contributed by resistance of ions migrating through separator pores. At decomposition temperature, separators begin to shrink, leading to short circuits between the two electrodes which may eventually cause thermal runaway. Differential scanning calorimetry (DSC) can be used to establish the melting temperature of separators.

Chapter 4 addresses the Influence of Temperature on Supercapacitor Performance. Though the heat generated in double layer capacitors is mostly from Joule heating determined by the internal resistance (or equivalent series resistance, ESR), in supercapacitors of the pseudo-capacitor type, both Joule and exothermic/endothermic Faradaic reactions contribute to the overall heat generation. This chapter presents detailed thermal behaviors of Aqueous Electrolytes, Organic Electrolytes, Ionic Liquids (IL) and Solid State / Polymer Gel Electrolytes, and their effects on capacitance and ESR. There is also good coverage on extreme low-temperature performance of electrolytes and methods to extend them beyond −55°C for space applications by using Organic electrolytes. In comparison, Li-ion batteries are known to exhibit poor low-temperature performance and are limited to −40°C.

On the extreme high-temperature side, for example, in downhole drilling where temperatures are above 120°C, the supercapacitors’ ability to function is limited by their electrolytes. Ionic liquids are used in high temperature applications because of their good thermal stability and low vapor pressure.

Chapter 4 also presents a statistical model to quantify the influence of operating voltage and temperature on the lifetime of the supercapacitors. The influence of temperature on the self-discharge of supercapacitors in open-circuit conditions is also discussed.

Chapter 5 on Thermal Modeling of Supercapacitors discusses thermal models to analyze the thermal behaviors of supercapacitors. The heat dissipation in supercapacitors can be broadly categorized as irreversible and reversible heating. Joule heating in supercapacitors is irreversible because it is positive during both the charge and discharge cycles. On the other hand, the reversible heat generation rate is positive during charging and negative during discharging.

The irreversible heat generation term is proportional to the square of the current whereas the reversible heat generation term is linearly proportional to the current. The temperature history observed experimentally during continuous charge/discharge cycling of a supercapacitor is a superposition of the heat generation due to the irreversible Joule heating which increases monotonically with time, and reversible heating which oscillates continuously. One important point this chapter brings out is that in supercapacitors with high thermal mass, these oscillations in temperature occur primarily at the core. The time required for the temperature to propagate to the surface is substantially longer than the charge/discharge duration. The oscillations can continue even after the supercapacitor reaches its steady-state temperature which may lead to additional thermal stresses in the component materials.

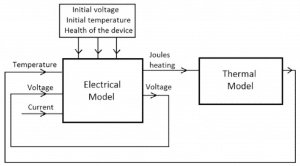

Chapter 5 also presents a good coverage on the electro-thermal models for supercapacitors. The electrical and thermal performances of a supercapacitor are closely interrelated, but some of the transport mechanisms like ionic and electronic transport, heat and mass transport are difficult to model in a coupled manner. Electro-thermal models offer one way to incorporate the coupled behavior. The figure below shows one approach using an equivalent circuit for a supercapacitor (eg., Randles Equivalent Circuit) which includes the electrolyte resistance in series.

Electro-thermal model of a supercapacitor (Source)

The chapter also presents lumped thermal models of the supercapacitor consisting of a combination of the conduction, convection and radiation thermal resistances, shown in the figure below. The chapter also discusses finite element approaches as well as Physics-based thermal models which account for reversible heat generation.

Equivalent circuit for heat transfer in a commercial supercapacitor

Lastly, Chapter 6 on Summary and Outlook discusses future work needed to better understand thermal behavior and performance of supercapacitors. Important among these are: electrode materials, thermally robust electrolytes, thermal characterization of micro-supercapacitors, and development of thermal models. In reference to the last, the authors of this book argue that better physics-based models are needed to understand thermal behavior of macro- and micro-supercapacitors, and also to provide a predictive capability in stark contrast to the largely interpretive nature of today’s models.

This book is an excellent source of material to understand the thermal effects in supercapacitors – a technology that is growing rapidly as witnessed by numerous product offerings and rigorous research. Supercapacitors represent a product category where thermal design and management takes a front seat in their design, installation, operation and service. In the coming months, Electronics Cooling will feature case studies on this topic.

Your comments are always welcome.

Book Information

Title Thermal Effects in Supercapacitors (2015)

Publisher Springer International Publishing

Authors Guoping Xiong, Arpan Kundu and Timothy S. Fisher

eBook ISBN 978-3-319-20242-6

DOI 10.1007/978-3-319-20242-6

Softcover ISBN 978-3-319-20241-9