Scott Johnson, Raytheon Space and Airborne Systems

Brendon Holt, Raytheon Missile Systems

Evolving trends within the aerospace industry are creating a new set of challenges that directly influence thermal management choices and planning that should be addressed in the early phases of the product development process. Within the functional side of the aerospace industry, the term “system architect” has been created to describe individuals with expertise in subsystem design, acquisition and integration. Hence, it is the position of the authors that the role of the thermal engineer must also evolve to have a similar systems perspective where the thermal performance is specified, simulated and measured from the component to system levels.

Based on past and recent experiences of the authors, there are four levels of interaction between thermal engineers and the product development process. The level of thermal engagement falls into four categories:

- Thermal Analysis. Interaction at this level is common to almost all product development efforts. The thermal engineer performs equation based and/or detailed thermal analysis using computational techniques and reports requirements compliance at the component level.

- Thermal Design. This level of interaction is also common to most product development efforts. The thermal engineer works in parallel with product design team to provide balanced design solutions that enable compliance with thermal design requirements.

- Thermal Systems Engineering. Interaction at this level is less common. The thermal engineer creates system level thermal performance models, uses these to derive and document thermal design requirements and then manages execution by product design teams across all program phases (design, build, qualification, production).

- Thermal Architect. Interaction between a thermal engineer and a product development activity at the architect level is desirable but infrequent. The thermal engineer engages during the pursuit and competition/capture phases of the program to determine best overall thermal systems approach that satisfies program objectives. The authors refer to this as Mission Level Engagement. Ideally, the thermal systems engineer and the thermal architect are the same individual.

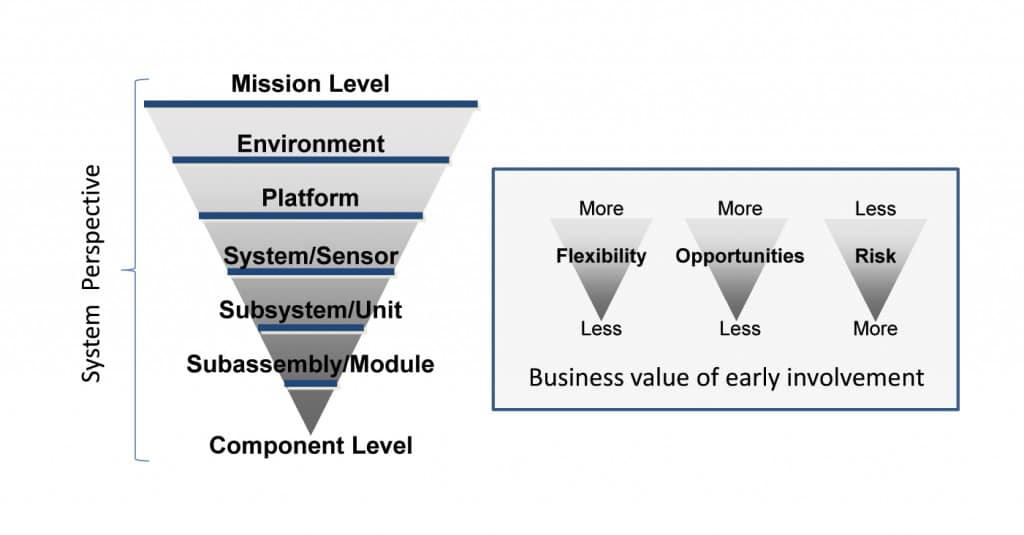

The impact of where these roles are applied in the product development process is illustrated in the left side of Figure 1. The highest perspective is the mission level and the lowest the component level. Ideally, the thermal architect would be engaged at the mission level (or as close as possible) early in the program pursuit and capture phases. The thermal architect would then transition to the role of thermal systems engineer, deriving and documenting thermal requirements at the system level and then managing thermal design and analysis activities at the subsystem, subassembly and component level. In general, thermal management and design decisions made at higher levels afford the benefits of more flexibility, more opportunities for design optimization and synergy, and less risk. These benefits are illustrated by the smaller inverted pyramids in the right side of Figure 1. From a business perspective, interaction with a thermal engineer at the mission level increases design flexibility and reduces risk.

At present, mission level engagement of the thermal architect is something of an idealization. Many product development activities simply are not structured to benefit from the engagement of a thermal engineer at the mission level. Also, mission level engagement of the thermal engineer would require something of a culture change within the industry and these are slow to occur. So in order to precipitate change in the culture the thermal engineer’s skill and tool set will have to evolve beyond the traditional thermal analysis and thermal design roles into the role of the thermal systems engineer and thermal architect. When it comes to modeling, the attributes most critical to the thermal architect and systems engineer’s effectiveness are speed and scalability. This means modeling only what is necessary and doing it quickly and with the needed accuracy and flexibility. This also means not being seduced by the siren’s call of the “rainbow plots” created using modern computational fluid dynamics (CFD) and simulation codes too early in the program. The level of detail required for these object based models is typically not available during the early phases of the program when thermal management decisions have the most impact.

In 2011, one of the author’s participated in a technology study derived from the Air Force Research Laboratories (AFRL) INVENT (Integrated Vehicle Energy Technology) initiative [1]. As part of the effort, a complete equation based transient model was created for a critical pod mounted sensor and integrated to run in MATLAB Simulink. This was combined with a platform (aircraft) level environmental cooling system (ECS) Simulink model and used to fly virtual missions. One of the objectives of the INVENT initiative was to extend this approach to integrate all of the platform critical energy subsystems. These would include energy “demand” functions like critical sensors and energy “supply” functions such as the engine, fuel delivery and electrical power generation subsystems. The benefit of this approach is true concurrent design at the mission level. The model evolves with the program and is used to actively manage the product development process. This is a real example of how a thermal engineer would function as a thermal architect engaging near the top of the System Perspective illustrated in Figure 1.

So what is the moral of this “facts and fairy tales” story. The fairy tale is that the role of the thermal engineer is defined entirely by thermal analysis. The fact is that acting as thermal architects, we have the opportunity to influence design choices at the earliest program phases in a way that maximizes product performance while minimizing technical and business risk.

References:

[1] http://acdl.mit.edu/mdo/mdo_10/INVENT%20M&S%20-%20Wolff.pdf