Thermal Facts and Fairy Tales: Automated Meshing Philosophy?

Peter Rodgers

Fairy tales are a well-established way to convey science and technology education. For example, a recent textbook [1] has documented how a range of Victorian-era (1837 – 1901) instructors used fairies and their tales to clarify scientific and technological concepts for young audiences. Today, elementary school curricula continue to incorporate fairy tale-style storytelling to enhance science, technology, engineering and math (STEM) education [2].

Others adopted a similar approach in the field of electronics-equipment cooling. During the 1990’s and early 2000’s, Kordyban [3-5] humorously chronicled the myths, mistakes, and “lessons learned” from practicing engineers involved in the field.

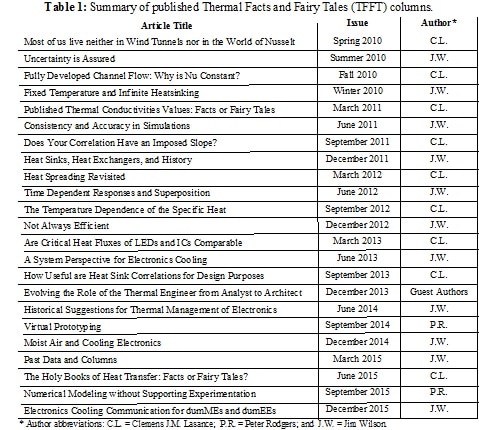

In a similar vein, ElectronicsCooling initiated the thermal facts and fairy tales (TFFT) column in Spring 2010 [6]. This edition’s TFFT is the twenty-fourth column, with all previous columns listed in Table 1. ElectronicsCooling has presented these “fairy tales” in an effort to help readers become more efficient in their daily jobs. It is also hoped that these columns have challenged some of your thinking and motivated you to better understand electronics cooling.

This TFFT column continues the theme of previous articles [7,8], documenting challenges encountered in computational fluid dynamics (CFD) modeling of electronics as a virtual prototyping tool.

Responding to the demand for improved design productivity, vendors of CFD codes have significantly enhanced code pre- and post-processing capabilities. One aspect of pre-processing enhancement is automated meshing. However, automated meshing is far from an exact science, as noted by the recent NASA commissioned report on its CFD vision for 2030 [9]. It might be tempting to believe that NASA’s 2030 goals for CFD analysis do not apply to electronics cooling. Nevertheless, NASA’s report presents a series of seven findings, one of which, Finding 4, states that “mesh generation and adaptivity continue to be significant bottlenecks in the CFD workflow, and very little government investment has been targeted in these areas” [10].

Generating a high-quality computational mesh for an electronic system is generally one of the most challenging tasks in CFD analysis. The mesh must both represent the geometry and capture the physics of the problem. Consequently, the concept of automated mesh generation is either considered as a dream of the CFD analysts who advocate it, or a fairy tale [10]. Before highlighting areas of caution with automated meshing, it should be noted that meshing is not truly a CFD issue.

The first area of concern for most users is coping with the practical meshing difficulties encountered for real-world CFD applications that have complex geometries (rather than idealized ones, such as flow over a flat plate!). When dealing with actual complex geometries, an automated mesh generator may fail to produce a mesh [11]. Alternatively, the automated mesher may generate a mesh that may not be optimum. Considering that the philosophy of automated meshing is to relieve the user of generating the mesh, the user may feel left with few or no tools for resolving such difficulties.

A second area of concern is that today’s meshing software is missing an important element; it has in-built intelligence to understand the geometry/topology of the computation domain, but generally not for understanding the physics of the problem. However, most CFD users expect to obtain reliable simulation results in one round of mesh generation. This is not impossible, but is often not the case. The involvement of the CFD solver is actually required during mesh generation. The typical CFD workflow:

Geometry –> Meshing –>Physics setup –> Solving –>Post-processing

may be considered flawed to some extent [12]. In this workflow, meshing is performed before the physical problem setup. Consequently, the meshing software has no information on the physics when generating the mesh, and the CFD solver “expects” a good mesh from its input file.

Either the CFD software or the user actually needs to understand the physics to ensure that the mesh quality is sufficient to capture the major physics. Unfortunately, meshing software and solver still generally do not communicate with each other directly, except in the case of mesh adaption [12]. The meshing software and solver only communicate through the formatted mesh file/input file. Therefore, to produce a satisfactory mesh, the above CFD workflow actually requires an iterative, trial-and-error procedure. This was not an issue in the past, but may be one today considering the productivity of design analysis requirements. To obtain more reliable predictions, today’s users still need to devote time to produce a satisfactory mesh quality, among other requirements, at the expense of a loss in design/analysis productivity. Such an approach ultimately has a cost benefit.

Until the meshing software acquires CFD intelligence – which will imply changes in the conventional CFD workflow – fully automated meshing may be considered a fairy tale. Will this change in the near future?

Finally, similarly to the now discontinued technical data columns published from 1997 to 2009 [13], at some point, the list of thermally relevant fairy tales will be exhausted and replaced by a new column topic. We welcome our readers’ inputs in suggesting new column topics.

References

[1] Keene, M., Science in Wonderland: The Scientific Fairy Tales of Victorian Britain, Oxford University Press, 2015.

[2] Get Caught Engineering, “Enchanted Engineering: Charming STEM Lessons with Fairy Tales,” http://www.getcaughtengineering.com/enchanted-engineering/, last retrieved on January 29, 2016.

[3] Kordyban, T., Hot Air Rises and Heat Sinks: Everything You Know About Cooling Electronics Is Wrong, ASME Press, 1998.

[4] Kordyban, T., More Hot Air, ASME Press, 2005.

[5] Kordyban, T., Kordyban’s Korner, ElectronicsCooling, https://electronics-cooling.com/category/kordybans-korner/, last retrieved on January 29, 2016.

[6] Lasance, C.J.M., 2010, “Thermal Facts & Fairy Tales: Most of us live neither in Wind Tunnels nor in the World of Nusselt,” ElectronicsCooling, https://electronics-cooling.com/2010/04/thermal-facts-and-fairy-tales-most-of-us-live-neither-in-wind-tunnels-nor-in-the-world-of-nusselt/, last retrieved on January 29, 2016.

[7] Rodgers, P., 2014, “Thermal Facts & Fairy Tales: Virtual Prototyping,” https://electronics-cooling.com/2014/09/thermal-facts-fairy-tales-virtual-prototyping/, last retrieved on January 29, 2016.

[8] Rodgers, P., 2015, “Thermal Facts & Fairy Tales: Numerical Modeling without Supporting Experimentation,” https://electronics-cooling.com/2015/09/thermal-facts-fairy-tales-numerical-modeling-without-supporting-experimentation/, last retrieved on January 29, 2016.

[9] Slotnick J., Khodadoust, A., Alonso, J., Darmofal, D., Gropp, W., Lurie, E., and Mavri-plis, D., “CFD Vision 2030 Study: A Path to Revolutionary Computational Aerosciences,” NASA/CR–2014-218178, March 2014, http://ntrs.nasa.gov/search.jsp?R=20140003093, last retrieved on January 29, 2016.

[10] Shengwei, M., 2012, “CFD in 2013: What Will Change? What Will Not: #1. Automated Mesh: A Classical Fairy Tale Continues,” http://caewatch.com/cfd-in-2013-what-will-be-changed-what-will-not/, last retrieved on January 29, 2016.

[11] Matus, R., 2011, “Meshing Philosophy: Automated or Automatic?” http://blog.pointwise.com/2011/02/03/meshing-philosophy-automated-or-automatic/, last retrieved on January 29, 2016.

[12] Shengwei, M., 2014, “CFD in 2014: Meshing, meshing, and meshing, the top 3 CFD problems in 2014,” http://caewatch.com/cfd-in-2014/, last retrieved on January 29, 2016.

[13] Wilson, J., 2015, “Thermal Facts and Fairy Tales: Past Data and Columns,” ElectronicsCooling, https://electronics-cooling.com/2015/03/thermal-facts-and-fairy-tales-past-data-and-columns/, last retrieved on January 29, 2016.