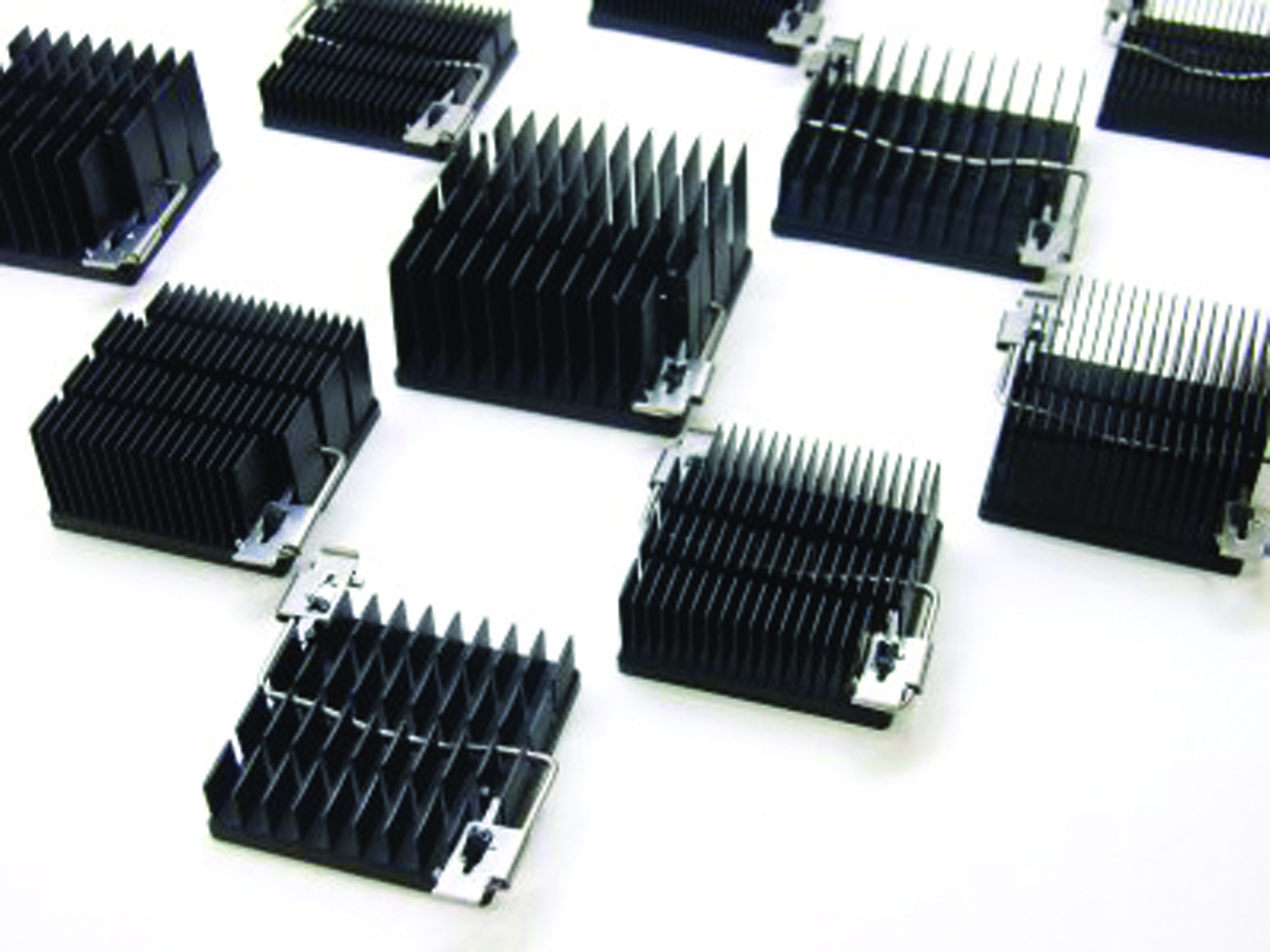

Alpha’s series of heat sinks feature an innovative attachment mechanism. Electronic components have become faster and more compact, generating more heat and increasing thermal densities. This has led to the u se of heat sinks of increased size and mass. One of the biggest challenges for thermal/mechanical engineers is mechanically mounting larger heat sinks while minimizing the amount board real estate used by the attachment mechanism. Generating sufficient attachment force is also critical with regard to mechanical security and proper performance of thermal interface materials. Alpha’s Quick Set series heat sinks have been designed to address both issues, providing secure and reliable attachment while requiring the absolute minimum of board real estate.

se of heat sinks of increased size and mass. One of the biggest challenges for thermal/mechanical engineers is mechanically mounting larger heat sinks while minimizing the amount board real estate used by the attachment mechanism. Generating sufficient attachment force is also critical with regard to mechanical security and proper performance of thermal interface materials. Alpha’s Quick Set series heat sinks have been designed to address both issues, providing secure and reliable attachment while requiring the absolute minimum of board real estate.

Mounting pins only require 1.8mm diameter holes in the PCB. Heat sinks are mechanically attached to the PCB instead of the chip package or substrate. Shock and vibration loads are transferred to the PCB instead of the chip and solder balls. Heat sink location and orientation is precisely set by anchor and pin. The possibility of damaging the chip, heat sink, or thermal interface material during installation is greatly reduced as well as the possibility of installing the heat sink in the wrong orientation or location.