Automotive aftermarket modification has both mass appeal and a multi-million dollar turnover. Neon underbody lighting, enhanced radiator systems, aero-dynamic side skirts and hood scoops are but some of the ways in which you can part with your hard earned cash for that unbeatable feeling of looking sideways at the person in the car next to you as you narrow your eyes and nod your head slowly, marvelling at the beauty of your own carriage compared to that of your hapless neighbour. “Awwwwwwwwww yeehhhhhhh”. “O dear” was the most I could muster when my eldest got excited about the colour of the lights inside a aftermarket desktop PC chassis he had his eye on.

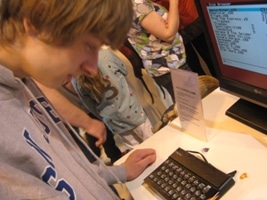

I took my two eldest boys to the NEC in Birmingham for ‘Gadget Show Live’ recently where there were halls and halls of vendors showing all types of electronic gizmos. From an audio shower (you stood under an innovative metal square plate acting as a speaker, where it played the sound of a shower?!) to a kettle with a simple hand pump so that you could control exactly how much water you needed to boil (bought as a present for the wife; note to other men: maybe you could do better than buy women kitchen appliances as presents, apparently I could have). Most fun though were the PC and gaming areas.

Why does so much effort go into the cooling of such systems? To ensure it doesn’t get too hot and thus fail is the obvious reason. The flip side of that is that you can ramp up the performance (and thus the power dissipation) more if you can remove the heat effectively enough. Welcome to the wonderful world of overclocking, more of that in part II.

24th May 2011, Nottingham